Izinto ezixutyiweyo ezenziwe nge-compound eqinileyo yesinyithi esirhabaxa kunye nesinyithi esibhindayo ngenkqubo ye-powder metallurgy. I-carbide enesamente ineempawu ezininzi ezintle ezifana nobunzima obuphezulu, ukumelana nokuguguleka, amandla alungileyo kunye nokuqina, ukumelana nobushushu kunye nokumelana nokugqwala, ngakumbi ubunzima bayo obuphezulu kunye nokumelana nokuguguleka, ezihlala zingatshintshi nokuba kubushushu obuyi-500 °C, zisenobunzima obuphezulu kwi-1000 ℃. I-Carbide isetyenziswa kakhulu njengezixhobo zesixhobo, ezifana nezixhobo zokujika, izixhobo zokusika, iiplaner, izixhobo zokubhola, izixhobo zokubhoboza, njl.njl., zokusika isinyithi esityhidiweyo, iintsimbi ezingezizo i-ferrous, iiplastiki, iifayibha zeekhemikhali, i-graphite, iglasi, ilitye kunye nentsimbi eqhelekileyo, kwaye ingasetyenziselwa ukusika izixhobo ezinzima kumatshini ezifana nentsimbi engatshiyo, intsimbi engatyiwayo, intsimbi ephezulu ye-manganese, intsimbi yesixhobo, njl. Isantya sokusika sezixhobo ezintsha ze-carbide ngoku siphindwe kalikhulu kunesentsimbi yekhabhoni.

Ukusetyenziswa kwe-carbide eqinisiweyo

(1) Izixhobo zesixhobo

I-Carbide yeyona nto ininzi yezixhobo, ezinokusetyenziselwa ukwenza izixhobo zokujika, izixhobo zokusika, iiplaner, iidrill, njl. Phakathi kwazo, i-tungsten-cobalt carbide ifanelekile ekucutshungulweni kweetshiphusi ezimfutshane zeentsimbi ze-ferrous nezingeyo-ferrous kunye nokucutshungulwa kwezinto ezingezizo zesinyithi, ezifana nesinyithi esityhidiweyo, ubhedu olutyhidiweyo, i-bakelite, njl.; i-tungsten-titanium-cobalt carbide ifanelekile ekucutshungulweni kweentsimbi ze-ferrous ixesha elide ezifana nentsimbi. Umatshini we-chip. Phakathi kwee-alloys ezifanayo, ezo zinomxholo we-cobalt omninzi zifanelekile ekucutshungulweni okurhabaxa, kwaye ezo zinomxholo we-cobalt omncinane zifanelekile ukugqitywa. Ii-carbide ezifakwe isamente ngokubanzi zinobomi obude kakhulu bomatshini kunezinye ii-carbide ezifakwe isamente kwizinto ezinzima ukuzifumana kumatshini ezifana nentsimbi engagqwali.

(2) Izinto zokubumba

I-carbide efakwe isamente isetyenziswa kakhulu kwii-dies zokusebenza ezibandayo ezifana nee-cold drawing dies, ii-cold punching dies, ii-cold extrusion dies, kunye nee-cold pier dies.

Ii-carbide cold heading dies ziyafuneka ukuze zibe nokuqina okuhle kwempembelelo, ukuqina kokuqhekeka, amandla okudinwa, amandla okugoba kunye nokumelana okuhle kokuguguleka phantsi kweemeko zokusebenza ezingagugiyo zokuguguleka okanye ukuguguleka okukhulu. Iiklasi ze-cobalt eziphakathi neziphezulu kunye ne-grain alloy zidla ngokusetyenziswa, njenge-YG15C.

Ngokubanzi, ubudlelwane phakathi kokuxhathisa ukuguguleka kunye nokuqina kwe-carbide eqinisiweyo buyaphikisana: ukwanda kokuxhathisa ukuguguleka kuya kukhokelela ekunciphiseni ukuguguleka, kwaye ukwanda kokuguguleka kuya kukhokelela ekunciphiseni ukuxhathisa ukuguguleka. Ke ngoko, xa ukhetha amanqanaba e-alloy, kuyimfuneko ukuhlangabezana neemfuno ezithile zokusetyenziswa ngokwezinto zokucubungula kunye neemeko zokusebenza zokucubungula.

Ukuba uhlobo olukhethiweyo lunokuqhekeka kwangethuba kwaye lonakale ngexesha lokusetyenziswa, kufuneka kukhethwe uhlobo olunobunzima obuphezulu; ukuba uhlobo olukhethiweyo lunokuqhekeka kwangethuba kwaye lonakale ngexesha lokusetyenziswa, kufuneka kukhethwe uhlobo olunobunzima obuphezulu kunye nokumelana nokuguguleka okungcono. . La manqanaba alandelayo: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Ukusuka ekhohlo ukuya ekunene, ubunzima buyehla, ukumelana nokuguguleka kuyehla, kwaye ubunzima buyenyuka; ngokuchaseneyo, okuchaseneyo kuyinyani.

(3) Izixhobo zokulinganisa kunye neendawo ezingagugiyo

I-Carbide isetyenziselwa izinto zokufaka umphezulu ezingagugiyo kunye nezixhobo zokulinganisa, iibheringi ezichanekileyo zee-grinders, iipleyiti zesikhokelo kunye neentonga zesikhokelo zee-grinders ezingenaziko, ii-top of lathes kunye nezinye iindawo ezingagugiyo.

Iintsimbi ze-binder zihlala ziintsimbi zeqela lesinyithi, ezidla ngokuba yi-cobalt kunye ne-nickel.

Xa kusenziwa i-carbide eqinisiweyo, ubukhulu be-particle ye-powder yezinto eziluhlaza ezikhethiweyo buphakathi kwe-1 kunye ne-2 microns, kwaye ubumsulwa buphezulu kakhulu. Izinto eziluhlaza zihlanganiswa ngokwe-composition ratio emiselweyo, kwaye utywala okanye ezinye izinto zongezwa kwi-grinding emanzi kwi-ball mill emanzi ukuze zidityaniswe ngokupheleleyo kwaye zicolwe. Hluza umxube. Emva koko, umxube uyaqhekeka, ucinezelwe, kwaye ufudunyezwe kubushushu obukufutshane nendawo yokunyibilika kwe-binder metal (1300-1500 °C), i-harded phase kunye ne-binder metal ziya kwenza i-eutectic alloy. Emva kokupholisa, i-harded phase zisasazwa kwi-grid eyenziwe yi-bonding metal kwaye zidibene ngokusondeleyo ukuze zenze i-solid whole. Ubunzima be-carbide eqinisiweyo buxhomekeke kumxholo we-harded phase kunye nobukhulu be-grain, oko kukuthi, xa umxholo we-harded phase uphezulu kwaye iinkozo zincinci, koba bukhulu ubunzima. Ukuqina kwe-carbide eqinisiweyo kuchazwa yi-binder metal. Okukhona umxholo we-binder metal uphezulu, kokukhona amandla e-flexural aphezulu.

Ngo-1923, uSchlerter waseJamani wongeza i-10% ukuya kwi-20% ye-cobalt kwi-tungsten carbide powder njenge-binder, waza wasungula i-alloy entsha ye-tungsten carbide kunye ne-cobalt. Ubulukhuni bulandela idayimani kuphela. I-carbide yokuqala eyenziwe ngesamente. Xa kunqunyulwa intsimbi ngesixhobo esenziwe ngale alloy, umphetho wokusika uya kuguga ngokukhawuleza, kwaye nomphetho wokusika uya kuqhekeka. Ngo-1929, uSchwarzkov eMelika wongeza inani elithile le-tungsten carbide kunye ne-titanium carbide compound carbides kwisakhiwo sokuqala, nto leyo eyaphucula ukusebenza kwesixhobo ekunqunyukeni intsimbi. Le yenye impumelelo kwimbali yophuhliso lwe-carbide eyenziwe ngesamente.

I-carbide enesamente ineempawu ezininzi ezintle ezifana nokuqina okuphezulu, ukumelana nokuguguleka, amandla alungileyo kunye nokuqina, ukumelana nobushushu kunye nokumelana nokugqwala, ngakumbi ubunzima bayo obuphezulu kunye nokumelana nokuguguleka, okungatshintshiyo nokuba kubushushu obuyi-500 °C, isenobunzima obuphezulu kwi-1000 ℃. I-Carbide isetyenziswa kakhulu njengezixhobo zezixhobo, ezifana nezixhobo zokujika, izixhobo zokusika, iiplaner, iidrill, izixhobo zokubhoboza, njl.njl., zokusika isinyithi esityhidiweyo, iintsimbi ezingezizo i-ferrous, iiplastiki, iifayibha zeekhemikhali, i-graphite, iglasi, ilitye kunye nentsimbi eqhelekileyo, kwaye ingasetyenziselwa ukusika izixhobo ezinzima ukuzifumana kumatshini ezifana nentsimbi engatshiyo, intsimbi engatyiwayo, intsimbi ephezulu ye-manganese, intsimbi yesixhobo, njl.njl. Isantya sokusika sezixhobo ezintsha ze-carbide ngoku siphindwe kalikhulu kunentsimbi yekhabhoni.

I-Carbide ingasetyenziselwa ukwenza izixhobo zokubhola amatye, izixhobo zemigodi, izixhobo zokubhola, izixhobo zokulinganisa, iindawo ezingagugiyo, izinto ezisusa isinyithi, ii-cylinder liners, ii-precision bearings, ii-nozzles, ii-metal molds (ezifana nee-wire drawing dies, ii-bolt dies, ii-nut dies, kunye nee-fastener molds ezahlukeneyo, ukusebenza kakuhle kwe-cemented carbide kwathatha indawo yee-steel molds zangaphambili kancinci kancinci).

Kamva, kwaphuma i-carbide efakwe isamente. Ngo-1969, iSweden yaphumelela ekuphuhliseni isixhobo esifakwe isamente se-titanium carbide. Isiseko sesixhobo yi-tungsten-titanium-cobalt carbide okanye i-tungsten-cobalt carbide. Ubukhulu be-titanium carbide coating kumphezulu buzii-microns ezimbalwa kuphela, kodwa xa kuthelekiswa nohlobo olufanayo lwezixhobo ze-alloy, Ubomi benkonzo buyandiswa kathathu, kwaye isantya sokusika sinyuswa ngama-25% ukuya kuma-50%. Kwiminyaka yoo-1970, kwavela isizukulwana sesine sezixhobo ezifakwe isamente zokusika izinto ezinzima ukusetyenzwa ngomatshini.

I-carbide efakwe isamente itshiswe njani?

I-carbide eqinisiweyo yinto yesinyithi eyenziwe nge-powder metallurgy yee-carbides kunye nee-binder metals zesinyithi esinye okanye ezingaphezulu ezichaseneyo.

Mamazwe avelisa izinto ezintsha

Kukho amazwe angaphezu kwama-50 ehlabathini avelisa i-carbide eqinisiweyo, enemveliso iyonke eyi-27,000-28,000t-. Abavelisi abaphambili yi-United States, iRashiya, iSweden, iTshayina, iJamani, iJapan, i-United Kingdom, iFrance, njl. Imarike ye-carbide eqinisiweyo yehlabathi igcwele kakhulu. , ukhuphiswano lwemarike lunamandla kakhulu. Ishishini le-carbide eqinisiweyo laseTshayina laqala ukubonakala ngasekupheleni kweminyaka yoo-1950. Ukususela kwiminyaka yoo-1960 ukuya koo-1970, ishishini le-carbide eqinisiweyo laseTshayina lakhula ngokukhawuleza. Ekuqaleni kweminyaka yoo-1990, amandla emveliso iyonke ye-carbide eqinisiweyo yaseTshayina afikelela kwi-6000t, kwaye imveliso iyonke ye-carbide eqinisiweyo ifikelele kwi-5000t, yesibini emva kweRashiya ne-United States, ikwindawo yesithathu kwihlabathi liphela.

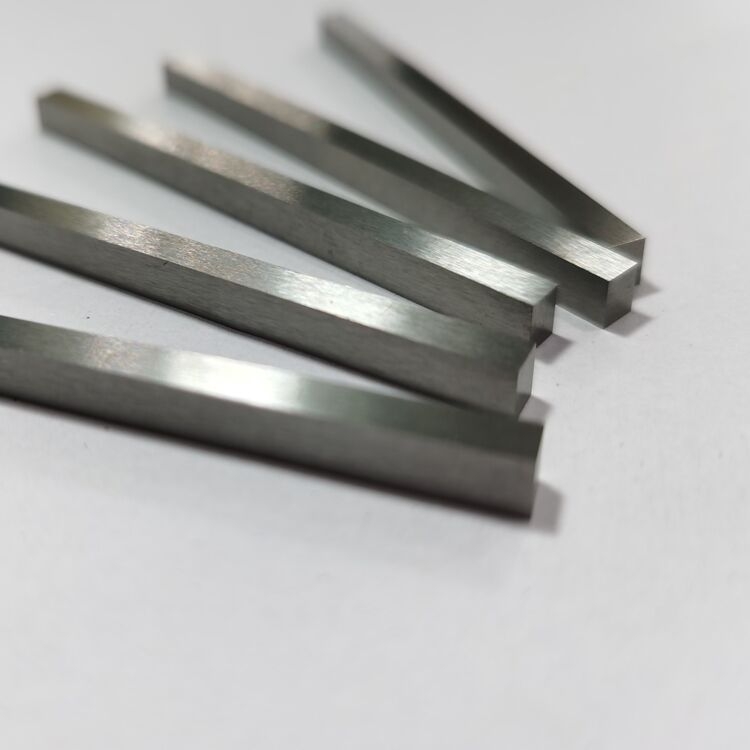

Umsiki weWC

①I-tungsten kunye ne-cobalt carbide eqinisiweyo

Izinto eziphambili yi-tungsten carbide (WC) kunye ne-binder cobalt (Co).

Uhlobo lwayo luqulathe “i-YG” (“i-hard and cobalt” kwi-Chinese Pinyin) kunye nepesenti yomxholo ophakathi we-cobalt.

Umzekelo, i-YG8 ithetha i-WCo=8% ephakathi, kwaye okuseleyo yi-tungsten-cobalt carbide ye-tungsten carbide.

Iimela ze-TIC

②Ikhabhayithi yeTungsten-titanium-cobalt

Izinto eziphambili yi-tungsten carbide, i-titanium carbide (TiC) kunye ne-cobalt.

Uhlobo lwayo lwenziwe ngoonobumba ababini abathi “YT” (“hard, titanium” kwisiqalo sePinyin yesiTshayina) kunye nomlinganiselo ophakathi wetitanium carbide.

Umzekelo, i-YT15 ithetha i-avareji ye-WTi=15%, kwaye okuseleyo yi-tungsten carbide kunye ne-tungsten-titanium-cobalt carbide enomxholo we-cobalt.

Isixhobo seTungsten Titanium Tantalum

③I-Tungsten-titanium-tantalum (niobium) ikhabhayithi eqinisiweyo

Izinto eziphambili yi-tungsten carbide, i-titanium carbide, i-tantalum carbide (okanye i-niobium carbide) kunye ne-cobalt. Olu hlobo lwe-cemented carbide lukwabizwa ngokuba yi-general cemented carbide okanye i-universal cemented carbide.

Uhlobo lwayo lwenziwe ngo-“YW” (isimaphambili sefonetiki yesiTshayina esithi “hard” kunye no-“wan”) kunye nenombolo yolandelelwano, efana ne-YW1.

Iimpawu zokusebenza

Izinto ezifakwe kwiCarbide Welded

Ubunzima obuphezulu (86 ~93HRA, obulingana ne-69 ~81HRC);

Ubunzima obuhle bobushushu (ukuya kuthi ga kwi-900 ~1000℃, gcina i-60HRC);

Ukumelana kakuhle nokukrweleka.

Izixhobo zokusika iikhabhayithi zikhawuleza ngokuphindwe ka-4 ukuya ku-7 kunentsimbi ekhawulezayo, kwaye ubomi besixhobo buphezulu ngokuphindwe ka-5 ukuya ku-80. Ukuvelisa izixhobo zokubumba kunye nokulinganisa, ubomi benkonzo buphezulu ngokuphindwe ka-20 ukuya ku-150 kunentsimbi yesixhobo se-alloy. Ingasika izinto eziqinileyo ezimalunga ne-50HRC.

Nangona kunjalo, i-carbide efakwe isamente iyaphuka kwaye ayinakwenziwa ngomatshini, kwaye kunzima ukwenza izixhobo ezihlanganisiweyo ezineemilo ezintsonkothileyo. Ke ngoko, kudla ngokwenziwa iiblade zeemilo ezahlukeneyo, ezifakwa emzimbeni wesixhobo okanye emzimbeni wesikhunta ngokuwelda, ukubopha, ukubethela ngoomatshini, njl.njl.

Ibha enemilo ekhethekileyo

Ukusila

Ukubumba i-carbide enesamente kukucinezela umgubo kwi-billet, uze ungene kwi-oven yokufudumeza ukuya kubushushu obuthile (ubushushu bokutshiza), uyigcine ixesha elithile (ixesha lokubamba), uze uyipholise ukuze ufumane izinto ze-carbide ezinesamente ezineempawu ezifunekayo.

Inkqubo yokucocwa kwe-carbide eqinisiweyo inokwahlulwahlulwa ibe ngamanqanaba amane asisiseko:

1: Kwinqanaba lokususa i-arhente yokwenza kunye nokutshiza kwangaphambili, umzimba otshiziweyo utshintsha ngolu hlobo lulandelayo:

Ukususwa kwe-molding agent, kunye nokunyuka kobushushu kwinqanaba lokuqala lokusila, i-molding agent iyabola okanye iphele kancinci kancinci, kwaye umzimba osila awubandakanywa. Uhlobo, ubungakanani kunye nenkqubo yokusila zahlukile.

Ii-oxides ezikumphezulu womgubo ziyancitshiswa. Xa kushushu ukunyibilikisa, i-hydrogen inokunciphisa ii-oxides ze-cobalt kunye ne-tungsten. Ukuba i-agent yokwenza isusiwe kwi-vacuum kwaye itshiswe, impendulo ye-carbon-oxygen ayinamandla. Uxinzelelo loqhagamshelwano phakathi kwamasuntswana omgubo luyasuswa kancinci kancinci, umgubo wesinyithi obophayo uqala ukubuyela kwimeko yesiqhelo kwaye uphinde usetyenziswe, ukusasazeka komphezulu kuqala ukwenzeka, kwaye amandla e-briquetting ayaphucuka.

2: Isigaba sokusila esiqinileyo (ubushushu obungama-800℃–eutectic)

Kwiqondo lobushushu ngaphambi kokuba kuvele isigaba solwelo, ukongeza ekuqhubekeni kwenkqubo yesigaba sangaphambili, impendulo yesigaba esiqinileyo kunye nokusasazwa kwayo kuyaqiniswa, ukuhamba kweplastiki kuyandiswa, kwaye umzimba osikiweyo uncipha kakhulu.

3: Inqanaba lokusila lesigaba solwelo (ubushushu obuphuma e-eutectic - ubushushu bokusila)

Xa i-liquid phase ibonakala emzimbeni osikiweyo, ukuncipha kugqitywa ngokukhawuleza, kulandele utshintsho lwe-crystallographic ukuze kwenziwe isakhiwo esisisiseko kunye nesakhiwo se-alloy.

4: Inqanaba lokuphola (ubushushu bokutshiza - ubushushu begumbi)

Kule nqanaba, ulwakhiwo kunye nokwakheka kwesigaba se-alloy kuneenguqu ezithile kwiimeko ezahlukeneyo zokupholisa. Olu phawu lungasetyenziselwa ukufudumeza i-carbide efakwe isamente ukuphucula iimpawu zayo zomzimba nezoomatshini.

Ixesha lokuthumela: Epreli-11-2022