Zeziphi izinto ezisetyenziswa kwiiblade ze-tungsten carbide ekusebenzeni ngomthi? Zeziphi iiblade ze-tungsten carbide ekufuneka zibe lukhetho lwakho lokuqala?

Izixhobo zeIiblade zeTungsten Carbide: Iiblade ze-tungsten carbide Zenziwe kakhulu nge-tungsten carbide, eyinxalenye equlathe i-tungsten kunye ne-carbon. Le nto yaziwa ngobunzima bayo obungaqhelekanga, idla ngokulinganiselwa kubunzima obuyi-9.0 kwisikali se-Mohs, obufana nedayimani. Inkqubo yokuvelisa ibandakanya ukuxuba umgubo we-tungsten kunye nomgubo we-carbon, uze ucoca lo mxube kumaqondo obushushu aphezulu ukuze wenze i-carbide. Kwezinye iinkqubo, i-tungsten carbide iphuculwa ngakumbi nge-cobalt njenge-binder, enceda ekufezekiseni ulungelelwaniso phakathi kobunzima kunye nokuqina. Umxholo we-cobalt unokwahluka, okuchaphazela ukumelana kwe-blade kunye nokumelana nokuguguleka.

Tiiblade ze-ungsten carbideZenziwe kakhulu nge-tungsten carbide (WC), eyinxalenye ye-tungsten kunye ne-carbon. Le nto yaziwa ngokuba lukhuni kwayo, ukumelana nokuguguleka kwayo, kunye nokuqina kwayo, nto leyo eyenza ukuba ilungele ukusetyenziswa kwizixhobo zokusika, kuquka neebhleyidi zokhuni.

Izinto eziphambili kwiTungsten Carbide Blades:

I-Tungsten Carbide (WC): Eyona nto iphambili, inika ubulukhuni obubalaseleyo kunye nokumelana nokuguguleka.

I-Cobalt (Co): Isetyenziswa rhoqo njengesixhobo sokubopha ukubamba amasuntswana e-carbide kunye, iphucula ukuqina kunye nokumelana neempembelelo.

I-Nickel (Ni): Ngamanye amaxesha isetyenziselwa ukuphucula ukumelana nokugqwala.

I-Titanium okanye ezinye izinto ezidibanisa i-alloy: Kwezinye iimeko, ezinye izinto zingongezwa ukuphucula iimpawu ezithile, ezifana nokuzinza kobushushu.

Iiblade zeTungsten Carbide zokwenza umsebenzi wokhuni:

Xa ukhetha iiblade ze-tungsten carbide zokusebenza ngomthi, ezi zinto zilandelayo kufuneka zikhokele isigqibo sakho:

Uhlobo lweBlade:

Iiplaner Blades: Ukuze zithe tyaba okanye zithambise umphezulu womthi, iiplaner blades ze-tungsten carbide ezikumgangatho ophezulu zinika ubukhali nokusebenza okuhlala ixesha elide.

Iintloko zeSpiral Cutter: Ezi zibonelela ngokugqitywa okuthambileyo kwaye azikwazi ukuqhekeka, nto leyo ibalulekileyo ekusebenzeni ngomthi okusemgangathweni ophezulu.

Iiblade zeSaw: Iiblade zesaw zeTungsten carbide zilungele ukugawula imithi, iplywood, kunye nezinye izinto, njengoko zigcina ubukhali kwaye zimelana nokuguguleka.

Ii-Router Bits: Kwimisebenzi yokhuni ecolekileyo, ii-router bits ezineencam ze-carbide zithandwa ngenxa yokuba zigcina umphetho kakuhle kwaye zisebenza kakuhle ekusikeni.

Izicelo Zokusebenza Ngokhuni:

Iinkuni ezithambileyo: Ukuba usebenza kakhulu neenkuni ezithambileyo, iibhlade ezine-grit carbide ecolekileyo zinokwanela.

Iinkuni eziqinileyo: Kwizinto eziqinileyo neziqinileyo, kufuneka ukhethe iibhleyidi ezine-carbide eqinileyo, ezinika ukuqina okukhulu phantsi koxinzelelo oluphezulu lokusika.

Ukhetho Lokuqala lweeTungsten Carbide Blades kwi-Woodworking:

Ukucwangcisa kunye nokuthambisa umphezulu: Iiblade ze-tungsten carbide planer kunye neentloko ze-spiral cutter mazibe lukhetho lwakho lokuqala, njengoko zibonelela ngobukhali obuhlala ixesha elide kunye nokugqitywa okugudileyo.

Ukusika: Iiblade zesarha ze-tungsten carbide zilungile kakhulu ekusikeni iinkuni ezininzi ngaphandle kokukrazuka kakhulu, ingakumbi xa kusetyenzwa ngemithi enzima okanye izinto ezidityanisiweyo.

Ngokukhetha iiblade ze-tungsten carbide ezikumgangatho ophezulu ezenzelwe imisebenzi yakho ethile yokwenza umthi,'Kuya kuqinisekisa ukusebenza kakuhle kunye nobomi obude bezixhobo zakho.

Umzekelo, iiblade ezinomxholo ophezulu we-cobalt (malunga ne-12-15%) zisetyenziselwa usetyenziso olubandakanya imithwalo ephakathi ukuya kwephezulu yoxinzelelo, ngelixa ezo zine-cobalt ephantsi (6-9%) zikhethwa usetyenziso apho ubomi obude kunye nokumelana nokuguguleka kubekwa phambili.

Iiblade zeTungsten Carbide Tipped (TCT): Kwimisebenzi yokhuni, iiblade ze-TCT zihlala zicetyiswa njengokhetho lokuqala ngenxa yokuguquguquka kwazo kunye nobude bazo. Ezi blade zinamazinyo e-tungsten carbide adityaniswe emzimbeni wentsimbi, edibanisa ukuqina kunye nokugcinwa kobukhali be-carbide kunye nokuguquguquka kwentsimbi. Zifanelekile ukusika uluhlu lwezinto ezahlukeneyo ukusuka kwiinkuni ezilukhuni ukuya kwiintsimbi kunye neeplastiki, zibonelela ngokuchaneka kunye nokusika okucocekileyo. Iiblade ze-TCT ziluncedo kakhulu kubuchule bazo bokugcina ubukhali obude kuneeblade zentsimbi ekhawulezayo (HSS), nto leyo ethetha ukuba azilolwa rhoqo, nangona zinokubiza kakhulu kwangaphambili.

Iiblade zeCarbide zeTungsten eziqinileyo: Nangona zingaqhelekanga ngenxa yokuba buthathaka kunye nexabiso, iiblade ze-tungsten carbide eziqinileyo zinokuba lukhetho oluhle kakhulu kwizicelo ezithile, njengokusika izinto ezirhabaxa kakhulu okanye eziqinileyo apho ukugcinwa komphetho kubaluleke kakhulu. Nangona kunjalo, azicetyiswa njengokhetho lokuqala ngokubanzi ekusebenzeni ngomthi ngenxa yokuba buthathaka kunye nobunzima bokulola.

Ukukhetha Iblade Ngokwesicelo: Xa ukhetha iblade yakho yokuqala ye-tungsten carbide, cinga ngohlobo lomthi oza kusebenza ngawo. Kwimithi ethambileyo okanye umsebenzi wokhuni ngokubanzi, iblade ye-TCT enomxholo we-cobalt ophakathi inokwanela. Kwimithi elukhuni, ungafuna ukujonga iiblade ezineejometri ezithile ezilungiselelwe ukuqina, njengalezo ezine-40º i-engile yomphetho ebandakanyiweyo yezicelo ezibandakanya imithwalo yomothuko.

Fokanye uninzi lwabasebenzi beenkuni abaqala nge-tungsten carbide,I-blade ye-TCT Iza kuba lolona khetho lusebenzayo lokuqala, olubonelela ngokulinganisela phakathi kweendleko, ukusebenza, kunye nokulula kokusetyenziswa kwimisebenzi eyahlukeneyo yokusebenza ngomthi.

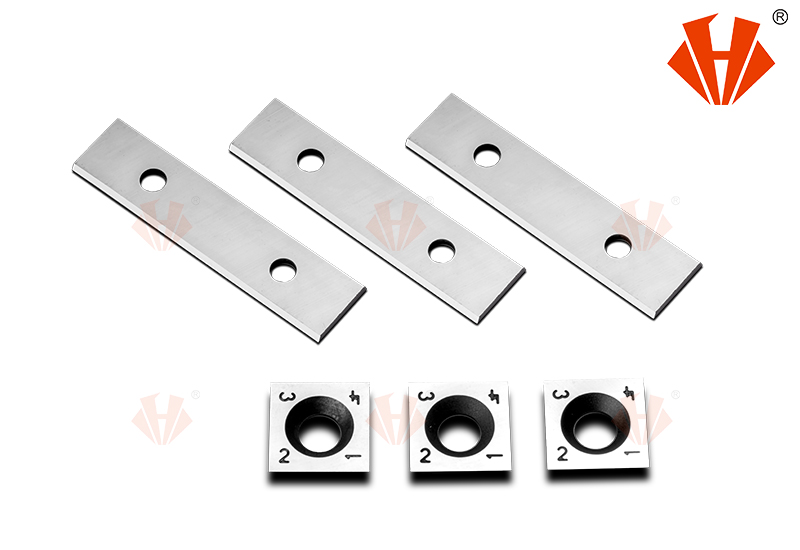

Iimela zePlaner eziGuquliweyo Iimela zenziwe nge-carbide yodidi oluphezulu kwaye zihlolwa nganye nganye ukuqinisekisa umgangatho kunye nokuchaneka. Iimela zePlaner zisetyenziswa xa kusetshenzwa kwiindawo zomthi ukunceda ekudaleni iindawo ezicwangciswe kakuhle. Zingasetyenziselwa ukutshiza, kunye nokurhoxisa imiphetho. Ubungakanani beblade bubhekisela kubungakanani beplaner enokuyilingana. Iya kuhlala ixesha elide kuneemela zeHSS eziqhelekileyo ubuncinane izihlandlo ezingama-20 kwaye ivelise ukugqitywa okuthambileyo nokucocekileyo.

I-Huxin Cemented Carbide(www.huaxincarbide.com)Igxile ekusebenziseni izixhobo eziphambili kunye neenkqubo zokwenza imveliso ukuvelisa iiblayidi ezibalaseleyo ngokuqina, ukumelana nokuguguleka, kunye nobukhali. Ubuchule babo kubuchwepheshe be-carbide bubenza babe liqabane elithembekileyo kumashishini afuna iiblayidi ze-carbide zokhuni ezikumgangatho ophezulu.

Qhagamshelana:lisa@hx-carbide.com

Ixesha leposi: Jan-08-2025