Ukumelana nokuguguleka okungaqhelekangaiiblade ze-tungsten carbideNangona ingcono kunezinye izixhobo zokusika ezininzi, nangona kunjalo isengozini yokuwohloka kancinci kancinci ngokusebenzisa iindlela ezininzi ngaxeshanye xa isebenza ngokuqhubekayo kangangexesha elide. Ukuqonda ezi nkqubo zokuguguleka kubalulekile ekuphuhliseni amanyathelo okulwa ngempumelelo kunye nokuphucula ukusebenza kweeblade kwizicelo zoshishino.

1. Iimpahla ezirhabaxa

Ukuguguleka okurhabaxa kubonisa enye yeendlela zokuguguleka eziqhelekileyo nezibalulekileyo kwezoqoqosho ezichaphazelaiiblade ze-tungsten carbideisebenza ngokuqhubekayo. Le nkqubo yenzeka xa izinto eziqinileyo okanye amasuntswana aqiniswe ngumsebenzi kwizinto zokusebenza zidibana ngoomatshini nomphezulu weblade, nto leyo ekhokelela ekususweni kwezinto kancinci kancinci ngezenzo zokusika nokulima. Ubunzima obukhulu beiinkozo ze-tungsten carbideinika ukumelana okukhulu nale ndlela yokuguguleka, kodwa isigaba se-cobalt binder esithambileyo sichaphazeleka lula kukuguguleka, okunokukhokelela ekuphumeni kweengqolowa ze-WC kunye nokuqhekeka kwazo okulandelayo okanye ukutsalwa kwazo. Uphando lubonisa ukuba ukuguguleka okurhabaxa kuxhaphake kakhulu xa kulungiswa izinto ezinezinto ezirhabaxa ezifana nee-silicon-aluminium alloys, izinto ezidityanisiweyo, okanye izinto zokusebenza ezinezikali zomphezulu eziqinileyo.

Izinga lokuguguleka okurhabaxa liphenjelelwa zizinto ezahlukeneyo, kuquka ubungakanani kunye nokwakheka kwamasuntswana arhabaxa, iimpawu zoomatshini zezinto zokusebenza kunye nezinto zeblade, kunye neemeko zokusika ezisetyenzisiweyo. Ukuqwalaselwa kwemizi-mveliso kuqinisekisa ukuba ukuguguleka okurhabaxa kudla ngokubonakala njengokuguguleka okufanayo kobuso becala lesixhobo okanye ukwakheka kwemijelo ecaleni komphezulu woqhagamshelwano lwetshiphusi, kunye nezinga lokuguguleka ngokubanzi lihambelana ngokuthe ngqo nomgama wokusika kwaye ngokuchaseneyo nobunzima bokusika.

2. Ukunxiba Okubanzi

Ukuguguleka kokusasaza, okwaziwa ngokuba kukuguguleka kokusasaza, kuba yinto ebaluleke kakhulu kwizicelo zoomatshini ezisebenzisa ubushushu obuphezulu apho amaqondo obushushu okusika adlula i-800°C. Kula maqondo obushushu aphezulu, izinto ezisetyenziswa kwiikhemikhali ze-tungsten carbide blade kunye nezinto zokusebenza ziya zitshintshatshintsha, nto leyo ekhokelela ekusasazekeni okufanayo kuyo yonke indawo yokusebenzisa izixhobo zokusebenza. Le nto ibonakala ngakumbi xa kusetyenzwa izinto ze-ferrous, apho intsimbi evela kwisixhobo somsebenzi inokusasaza iye kwi-carbide blade ngelixa ikhabhoni, i-tungsten, kunye ne-cobalt ezivela kwi-blade zisasazeka ziye kwi-chip material.

Inkqubo yokusasazwa itshintsha ngokusisiseko ukwakheka kunye neempawu zeeleya zomphezulu we-blade. Njengoko ii-athomu zekhabhoni zisuka kumphezulu we-blade, iikristale ze-WC ziyaphazamiseka, nto leyo ekhokelela ekunciphiseni ubulukhuni kunye nokuqina koomatshini. Kwangaxeshanye, ukusasazeka kwe-cobalt kunciphisa ukubopha phakathi kweenkozo ze-tungsten carbide, okuphazamisa ngakumbi ukuzinza kwe-blade. Oku kubola kweekhemikhali kudla ngokubangela ukwakheka kokuguguleka kwe-crater ebusweni be-rake yesixhobo, kunye nobunzulu bokuguguleka obuphezulu obuvela kwindawo yobushushu obuphezulu. Izifundo zibonise ukuba ukufaka i-titanium carbide (TiC) kwi-tungsten carbide composition kunokunciphisa kakhulu ukuguguleka kwe-diffusive ngenxa ye-TiC's diffusion coefficient ephantsi xa kuthelekiswa ne-WC kunye nokukwazi kwayo ukwenza iileya ze-titanium oxide ezikhuselayo kumaqondo obushushu aphezulu.

3. Ukunxiba okunamathelayo kunye neekhemikhali

Ukuguguleka kokuncamathelisa kwenzeka xa iziqwenga ezincinci zezinto zokusebenza zidityaniswa kumphezulu weblade phantsi kwempembelelo edibeneyo yoxinzelelo oluphezulu kunye nobushushu kwindawo yokusebenzisana kwesixhobo kunye nomsebenzi. Ezi ndawo zokuncamathelisa zinokuqhekeka emva koko ngexesha lokuhamba okufanelekileyo, okukhokelela ekususweni kwamasuntswana amancinci kumphezulu weblade. Le ndlela ixhaphake kakhulu xa kulungiswa izinto ezithambileyo ezinamathelayo.izixhobo zokusika, njengee-alloys ze-aluminium okanye iintsimbi ezithile ezingenasici.

Kwangaxeshanye, iinkqubo zokuguguleka kweekhemikhali, kuquka i-oxidation kunye nezinye iimpendulo ze-thermochemical, zinokuba negalelo elikhulu ekuwohlokeni kweeblade, ingakumbi kwiindawo ezishushu kakhulu.I-Tungsten carbideingenza i-oxidize ukuze yenze i-tungsten oxide kunye ne-carbon dioxide kumaqondo obushushu angaphezulu kwama-600°C, ngelixa izinto ze-cobalt binder nazo zichaphazeleka yi-oxidation, nto leyo enokubangela ukuba i-blade's blade binder phase iphele kwaye ilahleke ngeenkozo ze-tungsten carbide. Ukubakho kwezinto ezithile zeekhemikhali kwizixhobo zokusebenza, ezifana ne-chlorine okanye i-sulfur kwezinye ii-alloys, kunokukhawulezisa ezi nkqubo zokuguguleka kweekhemikhali ngokwenziwa kweemveliso ze-volatious okanye ze-low-strength reaction.

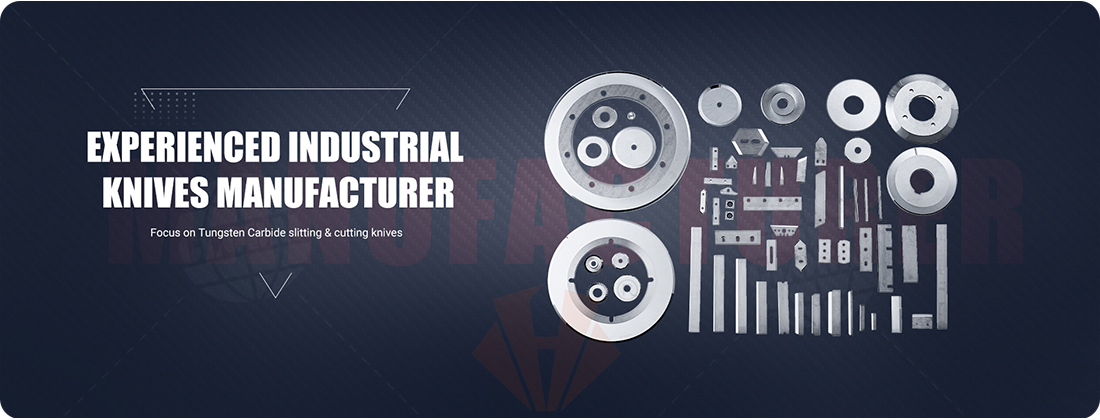

Malunga neHuaxin: Umenzi weeMeni zokuSika eziQinisekisiweyo zeTungsten Carbide

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ngumthengisi ochwephesha kunye nomvelisi weemveliso ze-tungsten carbide, ezinje ngeemela zokufaka ii-carbide zokwenza umsebenzi wokhuni, iimela ezijikelezayo ze-carbide zokwenza iintambo zokucoca icuba kunye necuba, iimela ezijikelezileyo zokwenza iikhadibhodi ezicoliweyo, iiblade ezintathu ze-razor/iiblade ezinemingxuma yokupakishwa, iteyipu, ukusika ifilimu encinci, iiblade ze-fiber cutter zoshishino lwelaphu njl.njl.

Ngophuhliso lweminyaka engaphezu kwama-25, iimveliso zethu zithunyelwe kwamanye amazwe e-US A, eRashiya, eMzantsi Melika, eIndiya, eTurkey, ePakistan, eOstreliya, eMzantsi-mpuma Asia njl. Ngomgangatho ogqwesileyo kunye namaxabiso akhuphisanayo, isimo sethu sengqondo sokusebenza nzima kunye nokuphendula kuyavunywa ngabathengi bethu. Kwaye singathanda ukuseka ubudlelwane obutsha beshishini nabathengi abatsha.

Qhagamshelana nathi namhlanje kwaye uya konwabela iingenelo zomgangatho olungileyo kunye neenkonzo ezivela kwiimveliso zethu!

Iimveliso zeeblade ze-tungsten carbide zoshishino ezisebenza kakuhle kakhulu

Inkonzo Yesiko

I-Huaxin Cemented Carbide yenza iiblade ze-tungsten carbide ezenziwe ngokwezifiso, iiblanks ezitshintshiweyo nezisemgangathweni kunye nee-preforms, ziqala kumgubo ukuya kwiiblanks ezigqityiweyo. Ukhetho lwethu olupheleleyo lwee-grades kunye nenkqubo yethu yokuvelisa inika izixhobo ezisebenza kakuhle nezithembekileyo ezikwi-intanethi ezijongana nemingeni ekhethekileyo yesicelo sabathengi kumashishini ahlukeneyo.

Izisombululo Ezilungiselelweyo Kushishino Ngalunye

iiblade ezenziwe ngokwezifiso

Umenzi okhokelayo weeblade zoshishino

Imibuzo eqhelekileyo yabathengi kunye neempendulo zeHuaxin

Oko kuxhomekeke kubungakanani, ngokubanzi iintsuku ezi-5-14. Njengomvelisi weeblade zoshishino, iHuaxin Cement Carbide iceba imveliso ngokwee-odolo kunye nezicelo zabathengi.

Ngokwesiqhelo iiveki ezi-3-6, ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Purchase & Delivery Conditions apha.

ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Thenga kunye neMiqathango yokuHanjiswaApha.

Ngokwesiqhelo i-T/T, iWestern Union...idiphozithi kuqala, Zonke ii-odolo zokuqala ezivela kubathengi abatsha zihlawulelwa kwangaphambili. Ezinye ii-odolo zinokuhlawulwa nge-invoyisi...Qhagamshelana nathiukwazi okungakumbi

Ewe, nxibelelana nathi, iimela zemizi-mveliso ziyafumaneka ngeendlela ezahlukeneyo, kuquka iimela ezibekwe phezulu, iimela ezijikelezileyo ezantsi, iimela ezinamazinyo aqinileyo/amazinyo, iimela ezijikelezileyo ezigqobhozayo, iimela ezithe tye, iimela ze-guillotine, iimela ezitsolo, iimela ezibukhali, kunye neemela ze-trapezoidal.

Ukuze sikuncede ufumane eyona blade ilungileyo, iHuaxin Cement Carbide ingakunika iiblade ezininzi zesampulu oza kuzivavanya kwimveliso. Ukuze usike kwaye uguqule izinto eziguquguqukayo ezifana nefilimu yeplastiki, ifoyile, ivinyl, iphepha, nezinye, sinikezela ngeeblade zokuguqula kuquka iiblade zeslitter ezinezikhewu kunye neeblade zerazor ezinezikhewu ezintathu. Sithumelele umbuzo ukuba unomdla kwiiblade zomatshini, kwaye siya kukunika isaphulelo. Iisampulu zeemela ezenziwe ngokwezifiso azifumaneki kodwa wamkelekile ukuba u-odole ubungakanani obuncinci be-odolo.

Zininzi iindlela eziya kwandisa ixesha elide kunye nobomi beshelufu beemela zakho zoshishino kunye neeblayidi ezikhoyo. Qhagamshelana nathi ukuze wazi malunga nendlela efanelekileyo yokupakishwa kweemela zoomatshini, iimeko zokugcina, ukufuma kunye nobushushu bomoya, kunye neengubo ezongezelelweyo eziya kukhusela iimela zakho kwaye zigcine ukusebenza kwazo kokusika.

Ixesha leposi: Oktobha-24-2025