Izixhobo zesixhobo se-carbide esifakwe isamente ziquka i-carbide efakwe isamente esekelwe kwi-tungsten carbide, i-carbide efakwe isamente esekelwe kwi-TiC(N), i-carbide efakwe isamente ene-TaC (NbC eyongeziweyo), kunye ne-carbide efakwe isamente e-ultrafine. Ukusebenza kwezixhobo ze-carbide ezifakwe isamente kuxhomekeka kakhulu kwizigaba zokuqinisa ezongeziweyo.

I-Carbide enesamente ene-TaC eyongeziweyo (i-NbC)

Ukongeza i-TaC (NbC) kwi-carbide eqinisiweyo yindlela esebenzayo yokuphucula ukusebenza kwayo. Kwii-alloys ze-TiC/Ni/Mo, ukutshintsha inxalenye ye-TiC ngee-carbides ezifana ne-WC kunye ne-TaC, ezinika ukuqina okungcono, kuphucula ukusebenza kwe-carbide eqinisiweyo kwaye kwandisa uluhlu lwesicelo sayo. Ukongezwa kwe-WC kunye ne-TaC kuphucula:

● Ukuqina

● Imodulus ethambileyo

● Ukuxhathisa ukuguqulwa kweplastiki

● Amandla obushushu obuphezulu

Ikwaphucula ukuhanjiswa kobushushu kunye nokumelana nokutshayiswa kobushushu, okwenza isixhobo sifaneleke ngakumbi ekusikeni okuphazamisekileyo. Kwii-WC-Co alloys, ukusebenza kungaphuculwa ngokongeza i-0.5% ukuya kwi-3% (inxalenye yobunzima) yee-carbides ezifana ne-TaC, i-NbC, i-Cr3C2, i-VC, i-TiC, okanye i-HfC. Iinjongo eziphambili ziquka:

● Ukucocwa kweenkozo

● Ukugcina isakhiwo sekristale esifanayo ngaphandle kokuphinda sisetyenziswe

● Ukwandisa ubulukhuni kunye nokumelana nokuguguleka ngaphandle kokuphazamisa ukuqina

Ukongeza, ezi zongezo ziyanceda:

● Ubunzima obuphezulu bobushushu

● Amandla obushushu obuphezulu

● Ukumelana ne-oxidation

Ngexesha lokusika, kwakheka ifilimu ye-oxide eqinileyo, ezihlawulelayo, ekwaziyo ukumelana nokuguguleka okunamathelayo kunye nokusasazeka xa kulungiswa iintsimbi okanye ii-alloys ezithile. Oku kuphucula ukumelana nokuguguleka kwesixhobo kwaye kwandisa amandla aso okumelana nokuguguleka kwe-crater kunye nokuguguleka kwe-flank. Ezi zibonelelo ziya zicaca ngakumbi njengoko umxholo we-cobalt kwi-carbide efakwe isamente usanda.

● I-carbide efakwe isamente ene-1% ukuya kwi-3% (inxalenye yobunzima) I-TaC (NbC) ingasebenzisa ii-iron ezahlukeneyo, kuquka i-iron eqinileyo kakhulu kunye ne-alloy cast iron.

● Ii-alloys ze-cobalt eziphantsi ezine-3% ukuya kwi-10% (inxalenye yobunzima) i-TaC (NbC), ezifana ne-YG6A, YG8N, kunye ne-YG813, zinokuguquguquka. Zingacutshungulwa:

Isinyithi esibandayo

Isinyithi esithambileyo

Iintsimbi ezingezizo ezomileyo

Izinto ezilukhuni ukusetyenzwa ngomatshini ezifana nentsimbi engagqwaliyo, intsimbi eqinileyo, kunye nee-alloys ezishushu kakhulu

Ezi zaziwa ngokubanzi njengee-alloys zeenjongo ezibanzi (YW). Ukwandisa umxholo we-cobalt ngokufanelekileyo kwandisa amandla kunye nokuqina kolu hlobo lwe-carbide efakwe isamente, okwenza ukuba ifaneleke kwi-machining erhabaxa kunye nokusikwa okuphazamisekileyo kwezinto ezinzima ukusetyenzwa ngomatshini. Izicelo ziquka:

● Ukukhuhla iintsimbi ezinkulu ezibunjiweyo nezingxobo

● Ukujika, ukuplanga, kunye nokusila intsimbi ye-austenitic kunye nee-alloys ezimelana nobushushu

● Umatshini wokwenza i-machining ngee-engile ezinkulu ze-reki, iindawo ezinkulu zokusika, kunye nesantya esiphakathi ukuya kwesiphantsi

● Ukuvula ngokurhabaxa iilathe ezizenzekelayo, ezizenzekelayo, kunye nezixhobo ezininzi

● Izixhobo zokwenza iidrill, ii-gear hobs, kunye nezinye izixhobo ezinamandla aphezulu**

Kwii-alloys ze-WC-TiC-Co, umxholo we-TiC ogqithisileyo wonyusa uvakalelo lokuqhekeka kobushushu, nto leyo ekhokelela ekubeni buthathaka ngakumbi. Ukongeza i-TaC kwii-alloys ze-WC-Ti-Co eziphantsi kwe-cobalt ephezulu kuyaphucuka:

● Ukuqina

● Ukumelana nobushushu

● Ukumelana ne-oxidation

Nangona i-TiC inciphisa ukumelana nobushushu, i-TaC iyayilungisa le nto, nto leyo eyenza i-alloy ifaneleke kwimisebenzi yokugaya. Ezinye iindlela ezingabizi kakhulu ezifana ne-NbC okanye ii-Hf-Nb carbides (inxalenye yobunzima: Hf-60%, Nb-40%) zingathatha indawo ye-TaC. Kwii-alloys ze-TiC-Ni-Mo, ukongeza i-TiN, i-WC, kunye ne-TaC ngaxeshanye kuphucula kakhulu:

● Ukuqina

● Amandla okugoba

● Ukumelana ne-oxidation

● Ukuqhuba kwe-thermal

kumaqondo obushushu aphezulu (900–1000°C).

I-Carbide enesamente ecoliweyo kakhulu

Ukucocwa kweenkozo ze-carbide eqinisiweyo kunciphisa ubukhulu besigaba esiqinileyo, kwandisa indawo yomphezulu weenkozo zesigaba esiqinileyo kunye namandla okubopha phakathi kweenkozo. Isigaba sokubopha sisasazeka ngokulinganayo kuzo, siphucula:

Ukuqina

Ukumelana nokunxiba

Ukwandisa umxholo we-cobalt ngokufanelekileyo kwandisa amandla okuguquguquka. I-carbide eqiniswe ngesamente ethambileyo kakhulu, eyenziwe ngamasuntswana amancinci kakhulu e-WC kunye ne-Co, idibanisa:

Ubunzima obukhulu be-carbide eqinisiweyo

Amandla entsimbi ekhawulezayo

Ukuthelekiswa kobukhulu beenkozo:

Ikhabhayithi eqhelekileyo eqinisiweyo: 3–5 μm

I-carbide eqinisiweyo ngokubanzi: ~1.5 μm

Ii-alloys ze-submicron-grained: 0.5–1 μm

I-carbide eqiniswe ngesamente ethambileyo kakhulu: Ubungakanani bengqolowa ye-WC ngaphantsi kwe-0.5 μm

Ukuphuculwa kweenkozo kuyaphucuka:

Ukuqina

Ukumelana nokunxiba

Amandla okugobeka

Ukumelana nokutshiza

Ubunzima obuphezulu bobushushu

Xa kuthelekiswa ne-carbide eqhelekileyo efakwe isamente yolwakhiwo olufanayo, i-carbide efakwe isamente enamafutha aphantsi kakhulu inikezela:

Ukwanda kobunzima obungaphezulu kwe-2 HRA

Ukonyuka kwamandla okugoba kwe-600–800 MPa

Iimpawu eziqhelekileyo:

Umxholo weCobalt: 9%–15%

Ubunzima: 90–93 HRA

Amandla okugobeka: 2000–3500 MPa

Amanqanaba aveliswa eTshayina aquka i-YS2 (YG10H, YG10HT), YM051 (YH1), YM052 (YH2), YM053 (YH3), YD05 (YC09), YD10 (YG1101), B60, YG610, YG643, kunye ne-YD05. Ngenxa yeenkozo zayo ezintle kakhulu, i-carbide enesamente ecolekileyo kakhulu inokugaywa ibe yimiphetho ebukhali kakhulu enoburhabaxa obuphantsi bomphezulu, nto leyo eyenza ukuba ifaneleke kwizixhobo ezichanekileyo ezifana nezi:

Iibroaches

Abagxeki

Iitovu ezichanekileyo

Igqwesile ekuchweni ngobunzulu obuncinci bokusika kunye namazinga okutya. Ikwafanelekile kwizixhobo ezincinci ezifana nezi:

Iidrill ezincinci

Izigawuli ezincinci zokusika

Iibroaches ezincinci

Iitovu ezincinci

Ukutshintsha izixhobo zentsimbi ezikhawulezayo, ubomi bayo bubude ngokuphindwe kayi-10–40, mhlawumbi bungaphezulu ngokuphindwe kayi-100. Izixhobo ze-carbide ezinesamente ye-ultrafine zilungele ngokukodwa ukwenziwa kwemishini:

Ii-alloys ezisekwe kwi-iron kunye ne-nickel ezisekwe kwi-alloys ezishushu kakhulu

Iialloy zeTitanium

Iintsimbi ezingenasici ezimelana nobushushu

Izinto ezitshiziweyo, ezidityanisiweyo, nezigqunyiweyo (umz., ezisekwe kwintsimbi, ezisekwe kwi-nickel, ezisekwe kwi-cobalt, ezizigubungeleyo ezizigubungeleyo eziqinileyo, uthotho lwe-cobalt-chromium-tungsten)

Iintsimbi ezinamandla kakhulu

Iintsimbi eziqinileyo

Izinto ezinobunzima obuphezulu ezifana nee-irons ezifakwe i-chromium ephezulu kunye ne-nickel-cooled

Xa kusetyenzwa izinto ezinzima ukusetyenzwa ngomatshini, ubomi bazo buhlala ixesha elide ngokuphindwe kathathu ukuya kwishumi kunelo le-carbide eqhelekileyo efakwe isamente.

Kutheni Ukhetha iChengduhuaxin Carbide?

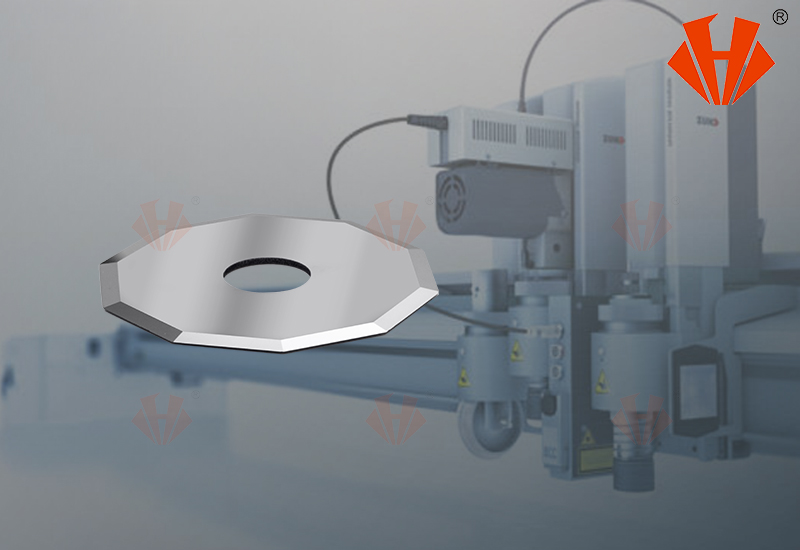

I-Chengduhuaxin Carbide ivelele kwimarike ngenxa yokuzinikela kwayo kumgangatho kunye nokuvelisa izinto ezintsha. Iiblade zabo zekhaphethi ze-tungsten carbide kunye neeblade ze-tungsten carbide ezifakwe kwi-slotted zenzelwe ukusebenza kakuhle, zibonelela abasebenzisi ngezixhobo ezibonelela ngokusika okucocekileyo nokuchanekileyo ngelixa bemelana nobunzima bokusetyenziswa kakhulu kwimizi-mveliso. Ngokugxila ekuqineni nasekusebenzeni kakuhle, iiblade ze-Chengduhuaxin Carbide ezifakwe kwi-slotted zibonelela ngesisombululo esifanelekileyo kumashishini afuna izixhobo zokusika ezinokuthenjwa.

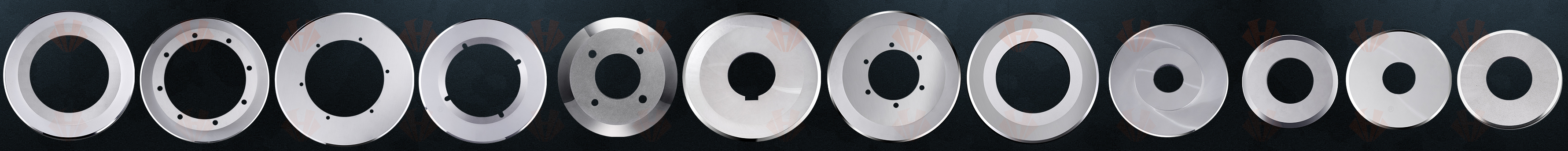

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ngumthengisi oqeqeshiweyo kunye nomvelisi weiimveliso ze-tungsten carbide,njengeemela zokufaka i-carbide zokusebenza ngomthi, i-carbideiimela ezijikelezayongenxaiintonga zokucoca icuba necuba, iimela ezijikelezileyo yokusika amakhadibhodi ane-corugat,iincakuba zereyiza ezinemingxuma emithathu/iincakuba ezinemingxuma yokupakisha, iteyiphu, ukusika ifilimu encinci, iiblade zokusika ifayibha kushishino lwelaphu njl.njl.

Ngophuhliso lweminyaka engaphezu kwama-25, iimveliso zethu zithunyelwe kwamanye amazwe e-US A, eRashiya, eMzantsi Melika, eIndiya, eTurkey, ePakistan, eOstreliya, eMzantsi-mpuma Asia njl. Ngomgangatho ogqwesileyo kunye namaxabiso akhuphisanayo, isimo sethu sengqondo sokusebenza nzima kunye nokuphendula kuyavunywa ngabathengi bethu. Kwaye singathanda ukuseka ubudlelwane obutsha beshishini nabathengi abatsha.

Qhagamshelana nathi namhlanje kwaye uya konwabela iingenelo zomgangatho olungileyo kunye neenkonzo ezivela kwiimveliso zethu!

Imibuzo eqhelekileyo yabathengi kunye neempendulo zeHuaxin

Oko kuxhomekeke kubungakanani, ngokubanzi iintsuku ezi-5-14. Njengomvelisi weeblade zoshishino, iHuaxin Cement Carbide iceba imveliso ngokwee-odolo kunye nezicelo zabathengi.

Ngokwesiqhelo iiveki ezi-3-6, ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Purchase & Delivery Conditions apha.

ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Thenga kunye neMiqathango yokuHanjiswaApha.

Ngokwesiqhelo i-T/T, iWestern Union...idiphozithi kuqala, Zonke ii-odolo zokuqala ezivela kubathengi abatsha zihlawulelwa kwangaphambili. Ezinye ii-odolo zinokuhlawulwa nge-invoyisi...Qhagamshelana nathiukwazi okungakumbi

Ewe, nxibelelana nathi, iimela zemizi-mveliso ziyafumaneka ngeendlela ezahlukeneyo, kuquka iimela ezibekwe phezulu, iimela ezijikelezileyo ezantsi, iimela ezinamazinyo aqinileyo/amazinyo, iimela ezijikelezileyo ezigqobhozayo, iimela ezithe tye, iimela ze-guillotine, iimela ezitsolo, iimela ezibukhali, kunye neemela ze-trapezoidal.

Ukuze sikuncede ufumane eyona blade ilungileyo, iHuaxin Cement Carbide ingakunika iiblade ezininzi zesampulu oza kuzivavanya kwimveliso. Ukuze usike kwaye uguqule izinto eziguquguqukayo ezifana nefilimu yeplastiki, ifoyile, ivinyl, iphepha, nezinye, sinikezela ngeeblade zokuguqula kuquka iiblade zeslitter ezinezikhewu kunye neeblade zerazor ezinezikhewu ezintathu. Sithumelele umbuzo ukuba unomdla kwiiblade zomatshini, kwaye siya kukunika isaphulelo. Iisampulu zeemela ezenziwe ngokwezifiso azifumaneki kodwa wamkelekile ukuba u-odole ubungakanani obuncinci be-odolo.

Zininzi iindlela eziya kwandisa ixesha elide kunye nobomi beshelufu beemela zakho zoshishino kunye neeblayidi ezikhoyo. Qhagamshelana nathi ukuze wazi malunga nendlela efanelekileyo yokupakishwa kweemela zoomatshini, iimeko zokugcina, ukufuma kunye nobushushu bomoya, kunye neengubo ezongezelelweyo eziya kukhusela iimela zakho kwaye zigcine ukusebenza kwazo kokusika.

Ixesha leposi: Julayi-14-2025