Ngokuqhubeka kwenzululwazi yezinto ezisetyenziswayo, uphuhliso kunye nokusetyenziswa kwe-tungsten carbide ekhethekileyo enganyangekiyo kukugqwala kuya kwandisa uluhlu lokusetyenziswa kwee-tungsten carbide blades. Ngokongeza izinto ezidibanisayo, ukuphucula iinkqubo zonyango lobushushu, kunye nokuphucula ubuchwepheshe bonyango lomphezulu, kulindeleke ukuba ii-tungsten carbide blades zexesha elizayo zigcine ukusebenza kakuhle kwiindawo ezahlukeneyo zokugqwala, zibonelela ngezisombululo zokucubungula ezinokuthenjwa nezisebenzayo kumashishini ahlukeneyo.

1. Malunga neeTungsten Carbide Blades

I-tungsten carbide, eyaziwa ngokuba yi-cemented carbide, yinto eyenziwe nge-alloy eyenziwe nge-tungsten carbide, eyenziwa ngenkqubo ye-powder metallurgy. Ibonakala ngokuqina okuphezulu kunye nokumelana nokuguguleka okugqwesileyo, igcina ubunzima bayo bungaguquki nokuba kuma-500°C kwaye isenobunzima obuphezulu kwi-1000°C. Olu buchule bubalaseleyo lwenza i-tungsten carbide ibe lukhetho oluhle kakhulu lokwenza izixhobo zokusika ezisebenza kakhulu, ezisetyenziswa kakhulu kwizixhobo ezahlukeneyo zokusika ezifana nezixhobo ze-lathe, izixhobo zokusika, ii-planers, ii-drill, kunye nezixhobo ezibophayo.

Iiblade ze-tungsten carbide zanamhlanje zenziwe ikakhulu zizinto ezimbini ezisisiseko: i-tungsten carbide kunye ne-cobalt. Isigaba esiqinileyo se-tungsten carbide sibonelela ngobunzima obukhulu kunye nokumelana nokuguguleka okufunekayo kwi-blade, ngelixa isigaba se-cobalt binder sinika ubungakanani obuthile bokuqina kwisixhobo. Kwindlela eqhelekileyo yokwakheka kweblade ye-tungsten carbide, i-tungsten carbide kunye ne-cobalt zithatha i-99% yento yonke, kunye nezinye iintsimbi ezenza i-1%. Esi sakhiwo sincinci sikhethekileyo sinika iiblade ze-tungsten carbide ubunzima obungenakufumaneka ngentsimbi ekhawulezayo kunye nokumelana nokuguguleka okugqitha kakhulu kwentsimbi yesixhobo esiqhelekileyo, ebambe isikhundla esibalulekileyo kwicandelo lokucubungula oomatshini.

Ngokuhambela phambili kwisayensi yezinto, usapho lwe-tungsten carbide lukwaphuhlise amanqanaba ahlukeneyo akhethekileyo, kuquka uluhlu oluninzi lwe-tungsten carbide engagugiyo kakhulu, i-tungsten carbide engagugiyo kakhulu, i-tungsten carbide engagugiyo kakhulu, i-tungsten carbide engagugiyo kakhulu, i-non-magnetic tungsten carbide, kunye ne-tungsten carbide ethambileyo kakhulu. Ezi zinto ze-tungsten carbide ezenziwe ngokwahlukileyo zibonelela ngezisombululo ezilungiselelweyo kwiimeko ezahlukeneyo zesicelo. Umzekelo, i-tungsten carbide engagugiyo esetyenziswa kwiindawo zeekhemikhali inokongeza izinto ezixutywayo ezifana ne-chromium kunye ne-nickel ukuphucula ngakumbi iipropati zayo zokulwa nokugqwala.

Uthelekiso Lokusebenza Kwezixhobo Eziqhelekileyo Zeblade

| Uhlobo lwezinto | Ubulukhuni (HRA) | Ukumelana nokunxiba | Ukuqina | Ukumelana nokugqwala |

| I-Tungsten Carbide eneCemented Carbide | 89-95 | Phezulu kakhulu | Phakathi | Phakathi ukuya kuLungileyo |

| Intsimbi Ekhawulezayo | 80-85 | Phakathi | Kulungile | Phakathi |

| Isixhobo sentsimbi | 70-75 | Phakathi | Kulungile | Phakathi |

| Iiblade zeCeramic | 92-95 | Phezulu kakhulu | Iphantsi | Igqwesile |

Uhlalutyo Lokusebenza Kokumelana Nokugqwala Kwee-Tungsten Carbide Blades

1. Iindlela kunye neempawu zokuxhathisa ukugqwala

Ukumelana nokugqwala kweeblade ze-tungsten carbide ngokuyintloko kuvela kulwakhiwo lwazo olukhethekileyo lweekhemikhali kunye nesakhiwo sazo esincinci. I-tungsten carbide esisiseko ine-tungsten carbide kunye ne-cobalt. I-tungsten carbide ngokwayo inozinzo olukhulu lweekhemikhali kwaye inokumelana nokukhukuliseka yimidiya eyahlukeneyo. Isigaba se-cobalt binder sinokwenza umaleko we-oxide okhuselayo kubushushu begumbi, nto leyo enciphisa inkqubo yokugqwala ngakumbi. Kwimisebenzi ebonakalayo, i-tungsten carbide ibonisa ukumelana okuthile nee-asidi, ii-alkalis, amanzi anetyuwa, kunye nezinye iikhemikhali, nto leyo evumela ukuba igcine ukusebenza okuzinzileyo kwiindawo ezahlukeneyo zokugqwala.

Uphando lubonisa ukuba ukumelana nokugqwala kwe-tungsten carbide kugqwesile kakhulu kwiindawo ezithile. Umzekelo, kwiimvavanyo zokugqwala kolwelo lwe-aluminium, izinga lokugqwala eliphakathi le-tungsten ecocekileyo limalunga ne-1/14 kuphela kunele-H13 steel, nto leyo ebonisa ukumelana nokugqwala okugqwesileyo. Olu buchule buphezulu bokulwa nokugqwala lwenza i-tungsten carbide ibe yindlela efanelekileyo kunentsimbi yendabuko kwishishini lezinto eziqanjiweyo kunye neendawo zeekhemikhali ezishushu kakhulu. Ngokufanayo, kwiimvavanyo zokugqwala kwee-alloys ze-tungsten ezinomxhuzulane ophezulu, abaphandi bafumanise ukuba ezi zinto zihlala zinokumelana nokugqwala okunamandla, zigcina ubunzulu besakhiwo emva kovavanyo lokugqwala olufakwe kwilebhu kunye novavanyo lokuvezwa kwendalo.

2. Iimpawu zomphezulu kunye nokuziphatha kokugqwala

Ukumelana nokugqwala kweeblade ze-tungsten carbide akuxhomekanga kuphela kwisixhobo ngokwaso kodwa nakwimeko yaso yomphezulu kunye nokulungiswa kwaso emva kokusetyenziswa. Umphezulu ocoliweyo nocoliweyo weblade ye-tungsten carbide unokwenza umaleko okhuselayo omncinci, othintela ngempumelelo ukungena kweendaba ezigqwalisayo. Ezinye iiblade ze-tungsten carbide eziphezulu zisebenzisa ubuchwepheshe bokugquma umphezulu (ezifana ne-TiN, i-TiCN, i-DLC, njl.njl.), ezingaphuculi kuphela ukusebenza kokusika kweblade kodwa zikwaphucula kakhulu ukumelana nokugqwala.

Kubalulekile ukuqaphela ukuba ukumelana nokugqwala kwe-tungsten carbide akulunganga ngokupheleleyo. Izifundo zibonisa ukuba phantsi kokuvezwa kwendalo ixesha elide, isigaba se-binder kwizixhobo ze-tungsten alloy sinomkhwa othile wokugqwala, okunokukhokelela ekunciphiseni kwe-plasticity yezinto. Le meko ikwakho nakwi-tungsten carbide eqhelekileyo enesigaba se-cobalt binder. Xa zikwiindawo ezithile zokugqwala ezifana nokufuma kunye netyuwa, isigaba se-cobalt sinokugqwala ngokukhethekileyo, ngaloo ndlela sichaphazele ukusebenza ngokubanzi kweblade. Ke ngoko, ukukhetha amanqanaba e-tungsten carbide anganyangekiyo ngokukodwa kukubaluleke kakhulu kwiimeko zokusetyenziswa ezineengozi eziphezulu zokugqwala.

3. Uphuhliso kunye neNtlalo-phambili yeTungsten Carbide enganyangekiyo kukugqwala

Ukuze kuhlangatyezwane neemfuno zesicelo kwiindawo ezishushu ezifana namashishini eekhemikhali kunye nolwandle, izazinzulu zezinto zenze iimodeli ze-tungsten carbide ezilungiselelwe ngokukodwa ukumelana nokugqwala. Ezi carbides ze-tungsten eziphambili ziphucula kakhulu uzinzo lweekhemikhali zezinto ngokongeza izinto ezixutywayo ezifana ne-chromium, i-nickel, kunye ne-molybdenum kwifomyula yendabuko. Umzekelo, i-blade ye-fiber yekhemikhali efakwe kwi-patent echasene nokugqwala kwe-sulfuric acid ngempumelelo inciphisa uburhabaxa be-tungsten carbide ngokwayo ngokusebenzisa iinkqubo ezikhethekileyo zokucima ioyile, ukubumba, kunye nokushisa, ngelixa ikwanika i-blade ukumelana okuhle nokugqwala kwe-sulfuric acid.

| Uhlobo lweNdalo | Isidanga sokuGqobhoka | Ifomu Ephambili Yokugqwala | Ukusebenza |

| Indawo Engqongileyo Yomoya | Isezantsi kakhulu | Ukuxinana kancinci | Igqwesile |

| Indawo eneasidi (pH<4) | Phakathi ukuya phezulu | Ukugqwala okuKhethiweyo kweSigaba seBinder | Ifuna iBanga eliKhethekileyo |

| Indalo ye-Alkaline (pH>9) | Ephantsi ukuya kwePhakathi | Ukugqwala komphezulu ofanayo | Ilungile ukuya kweLungileyo |

| Indalo Yamanzi Anetyuwa/Ulwandle | Phakathi | Ukugquma, Ukonakala kweCrevice | Ifuna Amanyathelo Okukhusela |

| Isinyithi Esinyibilikisiweyo Esinobushushu Obuphezulu | Iphantsi | Impendulo yoBuso | Igqwesile |

Ingxaki: Indlela Yokugqwala Kwezinto ZeTungsten Carbide Kwiindawo Ezihlukeneyo

Uhlalutyo Lokufaneleka Kwendalo: Iimeko Apho iTungsten Carbide Blades Excel

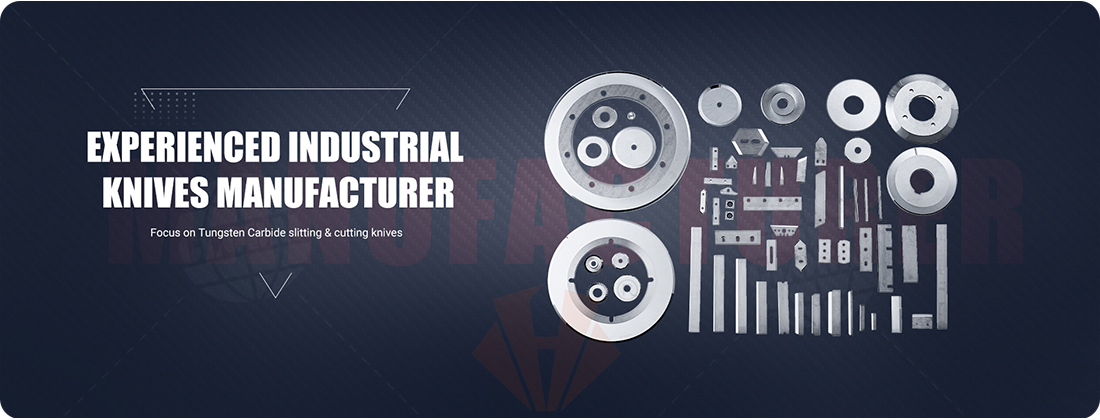

Malunga neHuaxin: Umenzi weeMeni zokuSika eziQinisekisiweyo zeTungsten Carbide

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ngumthengisi ochwephesha kunye nomvelisi weemveliso ze-tungsten carbide, ezinje ngeemela zokufaka ii-carbide zokwenza umsebenzi wokhuni, iimela ezijikelezayo ze-carbide zokwenza iintambo zokucoca icuba kunye necuba, iimela ezijikelezileyo zokwenza iikhadibhodi ezicoliweyo, iiblade ezintathu ze-razor/iiblade ezinemingxuma yokupakishwa, iteyipu, ukusika ifilimu encinci, iiblade ze-fiber cutter zoshishino lwelaphu njl.njl.

Ngophuhliso lweminyaka engaphezu kwama-25, iimveliso zethu zithunyelwe kwamanye amazwe e-US A, eRashiya, eMzantsi Melika, eIndiya, eTurkey, ePakistan, eOstreliya, eMzantsi-mpuma Asia njl. Ngomgangatho ogqwesileyo kunye namaxabiso akhuphisanayo, isimo sethu sengqondo sokusebenza nzima kunye nokuphendula kuyavunywa ngabathengi bethu. Kwaye singathanda ukuseka ubudlelwane obutsha beshishini nabathengi abatsha.

Qhagamshelana nathi namhlanje kwaye uya konwabela iingenelo zomgangatho olungileyo kunye neenkonzo ezivela kwiimveliso zethu!

Iimveliso zeeblade ze-tungsten carbide zoshishino ezisebenza kakuhle kakhulu

Inkonzo Yesiko

I-Huaxin Cemented Carbide yenza iiblade ze-tungsten carbide ezenziwe ngokwezifiso, iiblanks ezitshintshiweyo nezisemgangathweni kunye nee-preforms, ziqala kumgubo ukuya kwiiblanks ezigqityiweyo. Ukhetho lwethu olupheleleyo lwee-grades kunye nenkqubo yethu yokuvelisa inika izixhobo ezisebenza kakuhle nezithembekileyo ezikwi-intanethi ezijongana nemingeni ekhethekileyo yesicelo sabathengi kumashishini ahlukeneyo.

Izisombululo Ezilungiselelweyo Kushishino Ngalunye

iiblade ezenziwe ngokwezifiso

Umenzi okhokelayo weeblade zoshishino

Imibuzo eqhelekileyo yabathengi kunye neempendulo zeHuaxin

Oko kuxhomekeke kubungakanani, ngokubanzi iintsuku ezi-5-14. Njengomvelisi weeblade zoshishino, iHuaxin Cement Carbide iceba imveliso ngokwee-odolo kunye nezicelo zabathengi.

Ngokwesiqhelo iiveki ezi-3-6, ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Purchase & Delivery Conditions apha.

ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Thenga kunye neMiqathango yokuHanjiswaApha.

Ngokwesiqhelo i-T/T, iWestern Union...idiphozithi kuqala, Zonke ii-odolo zokuqala ezivela kubathengi abatsha zihlawulelwa kwangaphambili. Ezinye ii-odolo zinokuhlawulwa nge-invoyisi...Qhagamshelana nathiukwazi okungakumbi

Ewe, nxibelelana nathi, iimela zemizi-mveliso ziyafumaneka ngeendlela ezahlukeneyo, kuquka iimela ezibekwe phezulu, iimela ezijikelezileyo ezantsi, iimela ezinamazinyo aqinileyo/amazinyo, iimela ezijikelezileyo ezigqobhozayo, iimela ezithe tye, iimela ze-guillotine, iimela ezitsolo, iimela ezibukhali, kunye neemela ze-trapezoidal.

Ukuze sikuncede ufumane eyona blade ilungileyo, iHuaxin Cement Carbide ingakunika iiblade ezininzi zesampulu oza kuzivavanya kwimveliso. Ukuze usike kwaye uguqule izinto eziguquguqukayo ezifana nefilimu yeplastiki, ifoyile, ivinyl, iphepha, nezinye, sinikezela ngeeblade zokuguqula kuquka iiblade zeslitter ezinezikhewu kunye neeblade zerazor ezinezikhewu ezintathu. Sithumelele umbuzo ukuba unomdla kwiiblade zomatshini, kwaye siya kukunika isaphulelo. Iisampulu zeemela ezenziwe ngokwezifiso azifumaneki kodwa wamkelekile ukuba u-odole ubungakanani obuncinci be-odolo.

Zininzi iindlela eziya kwandisa ixesha elide kunye nobomi beshelufu beemela zakho zoshishino kunye neeblayidi ezikhoyo. Qhagamshelana nathi ukuze wazi malunga nendlela efanelekileyo yokupakishwa kweemela zoomatshini, iimeko zokugcina, ukufuma kunye nobushushu bomoya, kunye neengubo ezongezelelweyo eziya kukhusela iimela zakho kwaye zigcine ukusebenza kwazo kokusika.

Ixesha leposi: Oktobha-11-2025