TInkqubo yeZixhobo zokuGqibela/zoKubhala kunye neeBlade zazo ekusebenzeni ngomthi

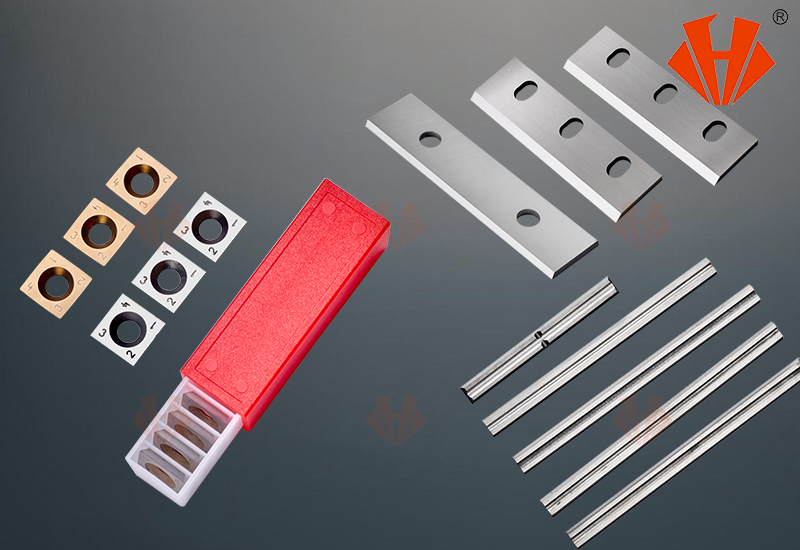

Kwicandelo lokusebenza ngomthi, ukongezwa kobume kunye ne-spirals kwiziqwenga eziguquliweyo kongeza kungekuphela nje ukutsala okubonakalayo kodwa nomdla ochukumisayo, okuguqula iindlela ezilula zibe yimisebenzi yobugcisa. Izixhobo zeNkqubo yokuGqibela/yokuGqibela yiseti ekhethekileyo yezixhobo ezenzelwe ukuphucula iiprojekthi zokujika iinkuni ngeepateni ezintsonkothileyo, i-spirals, kunye ne-textures. Apha, sijonga le nkqubo, izinto zayo, kunye nesizathu sokuba ii-tungsten carbide blades zilukhetho oluphezulu kwezi zixhobo.

Ukuqonda iNkqubo yokuGqibela/yokuThengisa

Isishwankathelo seZixhobo zokuGqibela kunye nokuThengisa:

Isixhobo Sokubhala: Esi sixhobo songeza ubume obukhethekileyo kumphezulu womthi, senza iziphumo ezifana ne-striations, i-whorls, okanye i-orenji peel finish. Ngokuqhelekileyo sinesixhobo sokusika esinokutshintshana esinokusebenza kwi-hardwoods ezithambileyo neziqinileyo, nangona iziphumo zinokuhluka ngokusekwe kwingqolowa yomthi kunye nobuninzi.

Isixhobo Sokujikeleza: Ezi zixhobo zisetyenziselwa ukwenza ii-spirals okanye iiflute, zinokwenza ii-spirals zesandla sasekhohlo nesasekunene. Zihlala zinenkqubo equka ukuphumla kwesixhobo kunye neendawo ezichazwe ngokweenkcukacha ukuze kuphindaphindwe rhoqo ii-spirals. Ubungakanani obahlukeneyo bokuphakama bunokufezekiswa ngokutshintsha umsiki okanye ukulungisa i-engile yesixhobo.

Izinto eziphambili:

- Isiphatho: Ngokwesiqhelo senziwe ngomthi ukuze sithuthuzeleke kwaye silawuleke, nto leyo evumela ukusetyenziswa ixesha elide ngaphandle kokudinwa.

- Ukuphumla kweSixhobo: Inxalenye ebalulekileyo yenkqubo yokujika, evumela ulawulo oluchanekileyo kwi-engile kunye nobunzulu bokusika.

- Abasiki: Intliziyo yezi zixhobo, ezifumaneka ngeendlela ezahlukeneyo:

- Izicuthi zokuThengisa: Ezi ziza ngoyilo olunye okanye ngaphezulu, zihlala zinemiphetho ephindwe kabini okanye iprofayili ethile ukwenza iitextures ezahlukeneyo.

- Izisiki ezijikelezayo: Zifumaneka kwiiseti, zihlala ziquka iipitshi ezahlukeneyo (ezifana ne-2mm, 4mm, 6mm) ukuze kufezekiswe iziphumo ezahlukeneyo ezijikelezayo.

Inzuzo yee-Tungsten Carbide Blades

Xa kufikwa kwiiblade ezisetyenziswa kwizixhobo zokujikajika kunye nezokuthungwa, i-tungsten carbide ikhethekile ngenxa yezizathu ezininzi ezibalulekileyo:

Ukuqina:

I-tungsten carbide yaziwa ngokuba lukhuni kwayo (igqithwa yidayimani kuphela), nto leyo ethetha ukuba la ma-blade agcina udini lwawo lude kakhulu kunee-blade zentsimbi zemveli. Oku kuhlala ixesha elide kuthetha ukuba izixhobo zihlala ixesha elide, kunciphisa ukuphindaphinda kokutshintshwa nokulolwa.

Ukugcinwa komda:

Ukugcinwa okuphezulu komphetho we-tungsten carbide kuqinisekisa ukuba ukusika ngakunye kuhlala kuchanekile ngokuhamba kwexesha, nto leyo ibalulekileyo ekufezekiseni iipateni zokuthungwa ezihambelanayo kunye nokujikajika. Olu phawu luluncedo ngakumbi ekusebenzeni ngomthi apho ukuchaneka kunokwenza umahluko omkhulu kubuhle.

Ukuguquguquka:

Ezi blade zinokusika iintlobo ngeentlobo zeenkuni, ukusuka kokuthambileyo ukuya kokuqinileyo, ngaphandle kokulahlekelwa bubukhali bazo ngokukhawuleza. Ukuguquguquka kwazo kuzenza zilungele iingcali ezisebenza ngeentlobo ezahlukeneyo zeenkuni kunye neeprojekthi.

Ukugcinwa Okuncitshisiweyo:

Nangona iiblade ze-tungsten carbide zinokuba nzima ukuzilola ngenxa yobunzima bazo, isidingo sokuzilola asixhaphakanga kangako. Eli candelo linomtsalane ngakumbi kwabo bafuna ukunciphisa ixesha lokungasebenzi kunye neendleko zokulungisa.

Ukusebenza kakuhle:

Ukukwazi ukusika umthi ngocoselelo ngaphandle komgudu omkhulu akupheleli nje ekukhawuleziseni inkqubo kodwa kunciphisa nobunzima bomzimba kumchweli, nto leyo evumela uyilo oluntsonkothileyo ngaphandle komgudu omkhulu.

Izicelo kunye nezinto ekufuneka ziqwalaselwe

- Ukusetyenziswa: Ezi zixhobo zisetyenziselwa ukuhombisa izinto ezijikiweyo ezifana neegoblets, iispindles, iikhandlela, kunye nezitya, zibonelela ngento yokuhombisa enokuba lula okanye ibonakale ngokusekwe kwindlela kunye nesixhobo esisetyenzisiweyo.

- Izinto ekufuneka ziqwalaselwe: Nangona iiblade ze-tungsten carbide ziyindlela entle yotyalo-mali, ziza nexabiso eliphezulu lokuqala. Nangona kunjalo, ixesha elide kunye nokusebenza kwazo kudla ngokuthethelela le ndleko. Kwakhona, abasebenzisi kufuneka baqaphele imfuneko yamanyathelo okhuseleko afanelekileyo xa besebenza ngezi zixhobo ngenxa yokuba zibukhali kwaye ziphuma kuthuli lomthi.

TInkqubo yezixhobo zokujika/zokulungisa, ezixhotyiswe ngeeblade ze-tungsten carbide, imele incopho kubuchwepheshe bezixhobo zokusebenza ngomthi, inika ulawulo olungenakuthelekiswa nanto, ukuchaneka, kunye nokuqina. Nokuba ungumguquli wemithi oyingcali okanye umntu othanda izinto azithandayo, ukutyala imali kwezi zixhobo kunokunyusa kakhulu iiprojekthi zakho zokuguqa ngomthi, kubonelele ngeenzuzo zobugcisa kunye nokusebenza. Khumbula, ukukhetha izinto zeeblade zakho kubaluleke kakhulu njengobuchule; i-tungsten carbide ayimelani nje nomsebenzi kodwa igqwesa kuwo.

Iimela zePlaner eziguqukayoZenziwe nge-carbide yodidi oluphezulu kwaye zihlolwa nganye nganye ukuqinisekisa umgangatho kunye nokuchaneka. Iiblade zeplaner zisetyenziswa xa kusetshenzwa kwiindawo zomthi ukunceda ekudaleni iindawo ezicwangciswe kakuhle. Zingasetyenziselwa ukutshiza, kunye nokubuyisela imiphetho. Ubungakanani beblade bubhekisela kubungakanani beplaner eza kufaneleka kuyo. Iya kuhlala ixesha elide kuneeblade zeHSS eziqhelekileyo ubuncinane izihlandlo ezingama-20 kwaye ivelise ukugqitywa okuthambileyo nokucocekileyo.

Abavelisi beHuaxin Cemented Carbideiiblade ze-tungsten carbideiiblanks kunye neepreforms ezenziwe ngokwezifiso, ezitshintshiweyo nezisemgangathweni, ukusuka kumgubo ukuya kwiiblanks ezigqityiweyo. Ukhetho lwethu olupheleleyo lweegreyidi kunye nenkqubo yethu yokuvelisa inika izixhobo ezisebenza kakuhle nezithembekileyo ezikwimo ye-intanethi ezijongana nemingeni ekhethekileyo yesicelo sabathengi kumashishini ahlukeneyo.

Izisombululo Ezilungiselelweyo Kushishino Ngalunye

iiblade ezenziwe ngokwezifiso

Umenzi okhokelayo weeblade zoshishino

www.huaxincarbide.com

contact: lisa@hx-carbide.com

Ixesha leposi: Jan-11-2025