Zenziwa njani iiblade ze-carbide?

Iiblade zekhabhayithi zixatyiswa ngenxa yobunzima bazo obungaqhelekanga, ukumelana nokuguguleka, kunye nokukwazi ukugcina ubukhali ixesha elide, nto leyo eyenza ukuba zilungele ukusika izinto eziqinileyo.

Iiblade ze-carbide zihlala zenziwa kusetyenziswa inkqubo equka ukunyibilikisa umgubo we-tungsten carbide ube yimo eqinileyo, kulandele ukubumba nokugqiba iblade. Nantsi inkcazo-ntetho yenyathelo ngenyathelo yendlela iiblade ze-carbide eziveliswa ngayo ngokubanzi:

1. Ukulungiswa kwezinto eziluhlaza

- I-Tungsten CarbideUmgubo: Izinto eziphambili ezisetyenziswa kwiiblade ze-carbide yi-tungsten carbide (WC), eyinxalenye eqinileyo neqinileyo ye-tungsten kunye ne-carbon. Uhlobo lomgubo lwe-tungsten carbide luxutywa nesinyithi esidibanisayo, esidla ngokuba yi-cobalt (Co), ukunceda kwinkqubo yokusila.

- Ukuxuba umgubo: Umgubo we-tungsten carbide kunye ne-cobalt zidityaniswe ndawonye ukuze zenze umxube ofanayo. Umxube ulawulwa ngononophelo ukuqinisekisa umxube ochanekileyo wobunzima kunye nokuqina kweblade oyifunayo.

2. Ukucinezela

- Ukubumba: Umxube wepowder ufakwa kwi-mold okanye kwi-die uze ucinezelwe kwimo encinci, engumfanekiso orhabaxa we-blade. Oku kwenziwa rhoqo phantsi koxinzelelo oluphezulu kwinkqubo ebizwa ngokuba yi-ukucinezela okubandayo kwe-isostatic (CIP) or ukucinezela okukodwa.

- Ukubumba: Ngexesha lokucinezela, imo erhabaxa yeblade iyakhiwa, kodwa ayikaqini ngokupheleleyo okanye ayikabi lukhuni. I-press inceda ukuxinanisa umxube we-powder kwi-geometry oyifunayo, njengemo yesixhobo sokusika okanye i-blade.

3. Ukusila

- Ukucoca ngobushushu obuphezuluEmva kokucinezela, i-blade idlula kwinkqubo yokutshiza. Oku kuquka ukufudumeza imo ecinezelweyo kwisithando somlilo kumaqondo obushushu aqhelekileyo phakathi1,400°C kunye ne-1,600°C(2552°F ukuya kwi-2912°F), nto leyo ebangela ukuba amasuntswana omgubo adibane aze enze into eqinileyo nexineneyo.

- Ukususwa kweBinder: Ngexesha lokusila, i-cobalt binder nayo iyacutshungulwa. Inceda amasuntswana e-tungsten carbide ukuba anamathele omnye komnye, kodwa emva kokusila, ikwanceda ukunika i-blade ubulukhuni bayo bokugqibela kunye nokuqina.

- Ukupholisa: Emva kokutsha, i-blade ipholiswa kancinci kancinci kwindawo elawulwayo ukuze kuthintelwe ukuqhekeka okanye ukugqwetheka.

4. Ukusila nokubumba

- UkusilaEmva kokurhawuzelela, i-carbide blade idla ngokuba rhabaxa kakhulu okanye ingaqhelekanga, ngoko ke iyagaywa ibe semgangathweni ochanekileyo kusetyenziswa amavili arhabaxa akhethekileyo okanye oomatshini bokugrumba. Eli nyathelo libalulekile ekudaleni umphetho obukhali nokuqinisekisa ukuba i-blade iyahlangabezana neemfuno ezifunekayo.

- Ukuyila kunye nokuProfayilisha: Ngokuxhomekeke kwindlela esetyenziswa ngayo, i-blade ingaphinda ibunjwe okanye ibekwe kwiprofayili. Oku kunokubandakanya ukugawula ii-engile ezithile kumphetho wokusika, ukufaka ii-coating, okanye ukulungisa i-geometry iyonke ye-blade.

5. Unyango Lokugqiba

- Iingubo zomphezulu (Ukhetho)Ezinye iiblade ze-carbide zifumana unyango olongezelelweyo, olufana nokugqunywa kwezinto ezifana ne-titanium nitride (TiN), ukuphucula ubulukhuni, ukumelana nokuguguleka, kunye nokunciphisa ukungqubana.

- Ukupolisha: Ukuze kuphuculwe ukusebenza, i-blade ingapholishwa ukuze kufumaneke umphezulu ogudileyo nogqityiweyo onciphisa ukungqubana kunye nokuphucula ukusebenza kakuhle kokusika.

6. Ulawulo loMgangatho kunye noVavanyo

- Uvavanyo loBulukhuni: Ukuqina kweblade kudla ngokuvavanywa ukuqinisekisa ukuba iyahlangabezana neemfuno ezifunekayo, kunye novavanyo oluqhelekileyo oluquka uvavanyo lokuqina kweRockwell okanye iVickers.

- Uvavanyo lweMilinganiselo: Ukuchaneka kubalulekile, ngoko ke ubukhulu beblade buyajongwa ukuqinisekisa ukuba buhlangabezana nobunzima obuchanekileyo.

- Uvavanyo Lokusebenza: Kwizicelo ezithile, ezinje ngokusika okanye ukunqumla, i-blade ingavavanywa ngokwenene ukuqinisekisa ukuba isebenza njengoko bekucetyiwe.

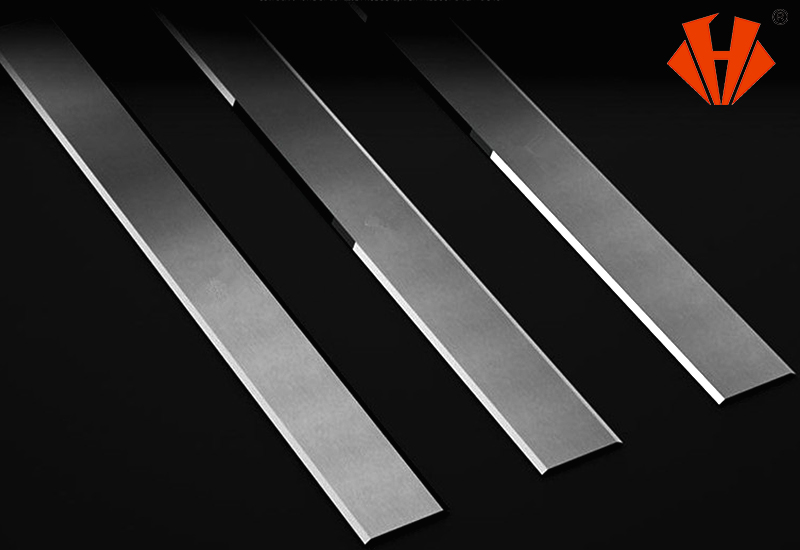

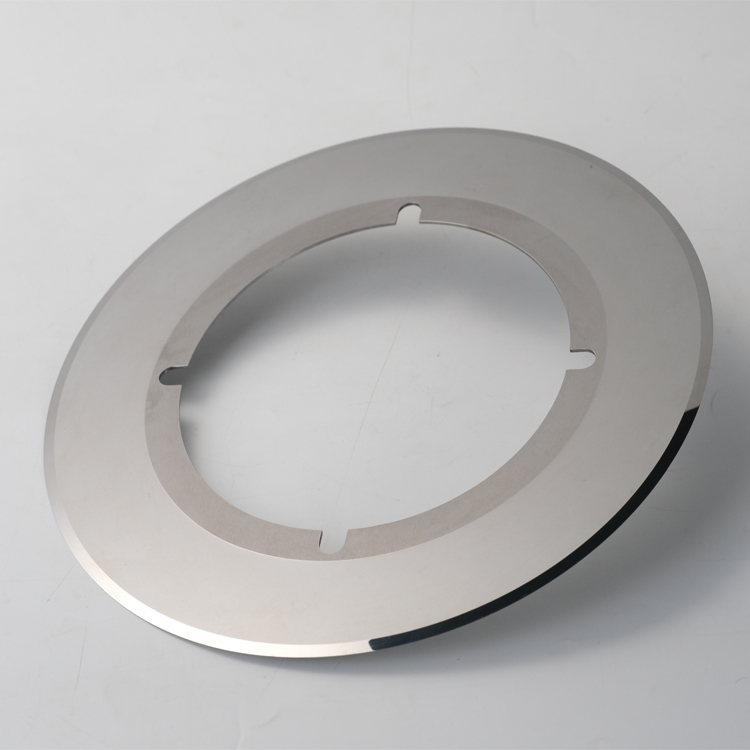

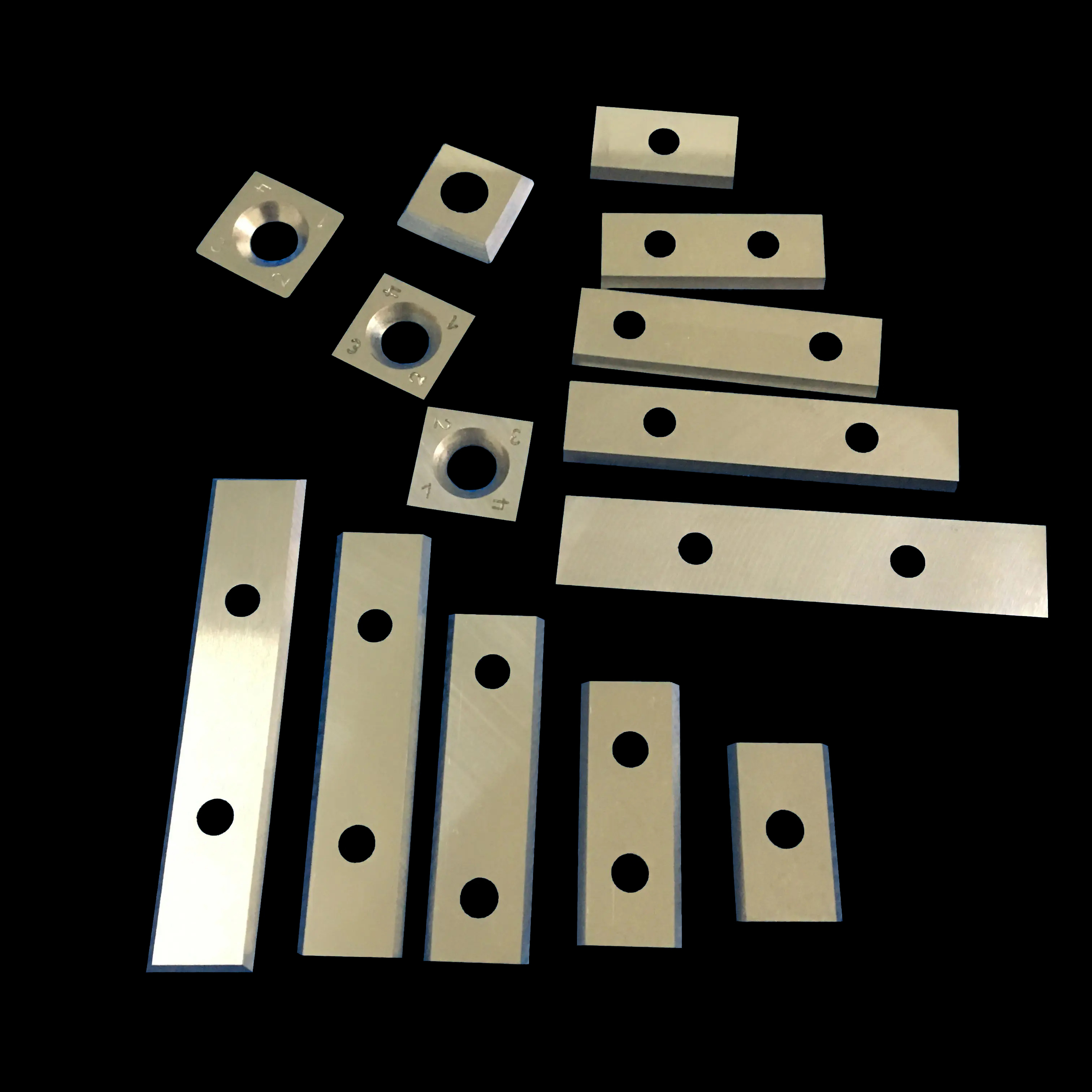

I-HUAXIN CARBIDE EQINISEKISIWEYO Ibonelela ngeemela ze-tungsten carbide kunye neeblade zexabiso eliphezulu kubathengi bethu abavela kumashishini ahlukeneyo kwihlabathi liphela. Iiblade zinokulungiswa ukuze zilingane noomatshini abasetyenziswa phantse kuyo nayiphi na inkqubo yemizi-mveliso. Izixhobo zeblade, ubude bomphetho kunye neeprofayili, unyango kunye neengubo zinokulungiswa ukuze zisetyenziswe nezixhobo ezininzi zoshishino.

Nje ukuba iiblayidi ziphumelele kuzo zonke iitshekhi zomgangatho, zilungele ukusetyenziswa kwizicelo ezahlukeneyo zoshishino, njengakwimisebenzi yesinyithi, ukupakisha, okanye eminye imisebenzi yokusika apho ukumelana nokuguguleka okuphezulu kunye nobukhali kubalulekile.

Ixesha leposi: Novemba-25-2024