Izixhobo ze-carbide ezifakwe isamente zilawula izixhobo zoomatshini be-CNC. Kwamanye amazwe, ngaphezulu kwe-90% yezixhobo zokujika kunye ne-55% yezixhobo zokugaya zenziwe nge-carbide efakwe isamente. Ukongeza, i-carbide efakwe isamente isetyenziswa kakhulu ukuvelisa izixhobo eziqhelekileyo ezifana nee-drill kunye ne-face milling cutters. Ukusetyenziswa kwe-carbide efakwe isamente kuyanda nakwizixhobo ezintsonkothileyo ezifana nee-reamers, ii-end mills, ii-medium and large modulus gear cutters zokulungisa iindawo zamazinyo eziqinileyo, kunye nee-broaches. Ukusebenza kakuhle kokusika kwezixhobo ze-carbide ezifakwe isamente kuphindwe ka-5 ukuya ku-8 kunezixhobo zentsimbi ekhawulezayo (HSS). Ubungakanani besinyithi esisusiweyo ngeyunithi nganye yomxholo we-tungsten bukhulu ngokuphindwe ka-5 kune-HSS. Ke ngoko, ukusebenzisa kakhulu i-carbide efakwe isamente njengesixhobo sesixhobo yenye yezona ndlela zisebenzayo zokusebenzisa izixhobo ngokufanelekileyo, ukuphucula imveliso yokusika, kunye nokuphucula iingenelo zoqoqosho.

Ulwahlulo lwezixhobo zeCarbide ezifakwe isamente

Ngokusekelwe kulwakhiwo oluphambili lweekhemikhali, i-carbide eqinisiweyo inokwahlulwa ibe yi-carbide eqinisiweyo esekelwe kwi-tungsten carbide kunye ne-carbide eqinisiweyo esekelwe kwi-titanium carbonitride (Ti(C,N)), njengoko kubonisiwe kwiTheyibhile 3-1.

I-carbide eyenziwe ngesamente esekelwe kwi-tungsten carbide ibandakanya:

I-Tungsten-cobalt (YG)

I-Tungsten-cobalt-titanium (YT)

Ngeekhabhayithi ezinqabileyo ezongeziweyo (YW)

Uhlobo ngalunye luneengenelo kunye neengxaki zalo. Ii-carbides ezongeziweyo ziquka i-tungsten carbide (WC), i-titanium carbide (TiC), i-tantalum carbide (TaC), i-niobium carbide (NbC), njl.njl., apho i-cobalt (Co) isetyenziswa kakhulu njenge-metal binder phase.

I-carbide eqinisiweyo esekelwe kwi-titanium carbonitride ngokuyintloko iqulathe i-TiC (ezinye zinezinye ii-carbides okanye ii-nitrides ezongeziweyo), kunye ne-molybdenum (Mo) kunye ne-nickel (Ni) njengezigaba zokubopha zesinyithi ezisetyenziswa rhoqo.

Ngokusekelwe kubungakanani beenkozo, i-carbide eqinisiweyo inokwahlulwahlulwa ibe:

I-carbide eqhelekileyo eqinisiweyo

I-carbide ecoliweyo ngesamente

I-carbide eqiniswe ngesamente ethambileyo kakhulu

Ngokutsho kwe-GB/T 2075—2007, iimpawu zoonobumba zezi zilandelayo:

I-HW: I-carbide engagqunywanga enesamente equlathe ikakhulu i-tungsten carbide (WC) enobukhulu beenkozo obuyi-≥1μm

HF: I-carbide engagqunywanga enesamente equlathe ikakhulu i-tungsten carbide (WC) enobukhulu beenkozo obuyi-<1μm

HT: I-carbide engagqunywanga enesamente equlathe ikakhulu i-titanium carbide (TiC) okanye i-titanium nitride (TiN) okanye zombini (ekwaziwa ngokuba yi-cermet)

HC: Iikhabhide ezifakwe isamente ezikhankanyiweyo apha ngasentla ezinesigqubuthelo

I-International Organisation for Standardization (ISO) ihlela ukusika ii-carbides ezinesamente zibe ziindidi ezintathu:

Iklasi ye-K (K10 ukuya kwi-K40):

Ilingana neklasi ye-YG yaseTshayina (eyakhiwe kakhulu yi-WC-Co)

Iklasi ye-P (P01 ukuya kwi-P50):

Ilingana neklasi ye-YT yaseTshayina (eyakhiwe kakhulu yi-WC-TiC-Co)

Iklasi ye-M (M10 ukuya kwi-M40):

Ilingana neklasi ye-YW yaseTshayina (eyakhiwe kakhulu yi-WC-TiC-TaC(NbC)-Co)

Amanqanaba odidi ngalunye amelwe linani eliphakathi kwe-01 ne-50, elibonisa uthotho lwee-alloys ukusuka kolona bunzima buphezulu ukuya kolona bunzima buphezulu, ukuze kukhethwe kwiinkqubo ezahlukeneyo zokusika kunye neemeko zomatshini wezinto zokusebenza ezahlukeneyo. Ukuba kuyimfuneko, ikhowudi ephakathi ingafakwa phakathi kweekhowudi ezimbini zokwahlulahlula ezikufutshane, ezifana ne-P15 phakathi kwe-P10 kunye ne-P20, okanye i-K25 phakathi kwe-K20 kunye ne-K30, kodwa kungabi ngaphezu kweyodwa. Kwiimeko ezikhethekileyo, ikhowudi yokwahlulahlula ye-P01 inokwahlulwahlulwa ngakumbi ngokongeza enye idijithi eyahlulwe yinqaku ledesimali, njenge-P01.1, P01.2, njl., ukuze kwahlulwe ngakumbi ukumelana nokuguguleka kunye nokuqina kwezinto zokugqiba imisebenzi.

Ukusebenza kwezixhobo zeCarbide ezifakwe isamente

1. UkuqinaI-carbide enesamente ineekhabhide ezininzi eziqinileyo (ezifana ne-WC, i-TiC), nto leyo eyenza ukuba ubunzima bayo bube phezulu kakhulu kunobo bezinto zentsimbi ezikhawulezayo. Okukhona ubunzima be-carbide enesamente buphezulu, kokukhona ikwazi ukumelana nokuguguleka kwayo, nto leyo edla ngokuba phezulu kakhulu kunobo bentsimbi ekhawulezayo.

Okukhona umxholo wesigaba se-cobalt binder uphezulu, kokukhona ubunzima be-alloy buphantsi.

Ekubeni iTiC inzima kuneWC, ii-alloys zeWC-TiC-Co zinobunzima obuphezulu kunee-alloys zeWC-Co. Okukhona umxholo weTiC ungaphezulu, kokukhona ubunzima buphezulu.

Ukongeza i-TaC kwii-alloys ze-WC-Co kwandisa ubulukhuni malunga ne-40 ukuya kwi-100 HV; ukongeza i-NbC kwandisa ubunzima bayo nge-70 ukuya kwi-150 HV.

2. Amandla Amandla okugoba ekhabhayithi eqinisiweyo ayi-1/3 ukuya kwi-1/2 kuphela kunalawo enziwe ngentsimbi ekhawulezayo.

Okukhona umxholo we-cobalt uphezulu, kokukhona amandla e-alloy ephezulu.

Ii-alloys ezine-TiC zinamandla aphantsi kunezo zingenayo i-TiC; okukhona umxholo we-TiC ungaphezulu, kokukhona amandla ehla.

Ukongeza i-TaC kwi-WC-TiC-Co cemented carbide kwandisa amandla ayo okugoba kwaye kwandisa kakhulu ukumelana komphetho ophambili ekuqhekekeni nasekuqhekekeni. Njengoko umxholo we-TaC usanda, amandla okudinwa nawo ayaphucuka.

Amandla okuxinwa kwekhabhayithi eqinisiweyo angaphezulu ngama-30% ukuya kuma-50% kunalawo entsimbi ekhawulezayo.

3. UkuqinaUkuqina kwekhabhayithi eqinisiweyo kuphantsi kakhulu kunokwentsimbi ekhawulezayo.

Ii-alloys ezine-TiC zinobunzima obuphantsi kunezo zingenayo i-TiC; njengoko umxholo we-TiC ukhula, ubunzima buyancipha.

Kwii-alloys ze-WC-TiC-Co, ukongeza ubungakanani obufanelekileyo be-TaC kunokunyusa ukuqina malunga ne-10% ngelixa kugcinwa ukumelana nobushushu kunye nokumelana nokuguguleka.

Ngenxa yokuqina kwayo okuphantsi, i-carbide eqinisiweyo ayifanelekanga kwiimeko ezineempembelelo ezinamandla okanye ukungcangcazela, ingakumbi kwisantya esiphantsi sokusika apho ukunamathela kunye nokuqhekeka kuqatha ngakumbi.

4. Iipropati zoBume boBushushuUkuhanjiswa kobushushu bekhabhayithi eqinisiweyo kungaphezulu ngokuphindwe kabini ukuya kathathu kunokwentsimbi ekhawulezayo.

Ekubeni i-TiC inamandla okuqhuba ubushushu aphantsi kune-WC, ii-WC-TiC-Co alloys zine-thermal conductivity ephantsi kune-WC-Co alloys. Okukhona umxholo we-TiC uphezulu, kokukhona i-thermal conductivity iphantsi.

5. Ukumelana nobushushu Ikhabhayithi enesamente inokumelana nobushushu okuphezulu kakhulu kunentsimbi ekhawulezayo kwaye inokwenza ukusika kwi-800 ukuya kwi-1000°C kwaye inokumelana kakuhle nokuguqulwa kweplastiki kumaqondo obushushu aphezulu.

Ukongeza i-TiC kwandisa ubulukhuni obuphezulu. Ekubeni ubushushu bokuthambisa be-TiC buphezulu kune-WC, ubulukhuni bee-alloys ze-WC-TiC-Co buyehla kancinci xa buthelekiswa nobushushu kune-WC-Co alloys. Okukhona i-TiC ininzi kwaye i-cobalt incinci, kokukhona incipha.

Ukongeza i-TaC okanye i-NbC (enezinga lokushisa eliphezulu lokuthambisa kune-TiC) kwandisa ngakumbi ubulukhuni namandla obushushu obuphezulu.

6. Iipropati zokunganamatheli Ubushushu bokunamathela kwikhabhayithi eqinisiweyo buphezulu kunobo bentsimbi ekhawulezayo, nto leyo eyinika ukumelana okungcono nokuguguleka kokunamathela.

Ubushushu bokunamathela kweCobalt ngentsimbi buphantsi kakhulu kune-WC's; njengoko umxholo we-cobalt unyuka, ubushushu bokunamathela buyancipha.

Ubushushu bokunamathela kweTiC buphezulu kuneeWC, ngoko ke ii-WC-TiC-Co alloys zinobushushu obuphezulu bokunamathela (malunga ne-100°C ngaphezulu) kunee-WC-Co alloys. I-TiO2 eyenziwe kubushushu obuphezulu ngexesha lokusika inciphisa ukunamathela.

I-TaC kunye ne-NbC zinobushushu obuphezulu bokunamathela kune-TiC, nto leyo ephucula iipropati zokulwa nokunamathela. Ukuthanda kwe-TaC izinto zokusebenza kuncinci kakhulu kunezinye ze-WC.

7. Uzinzo lweeKhemikhaliUkumelana nokuguguleka kwezixhobo zekhabhayithi ezifakwe isamente kunxulunyaniswa ngokusondeleyo nokuzinza kwazo ngokwasemzimbeni nangokweekhemikhali kumaqondo obushushu asebenzayo.

Ubushushu be-oxidation ye-carbide efakwe isamente buphezulu kunobo bentsimbi ekhawulezayo.

Ubushushu be-oxidation yeTiC buphezulu kakhulu kuneeWC, ngoko ke ii-alloys zeWC-TiC-Co zifumana ubunzima obuncinci be-oxidation kumaqondo obushushu aphezulu kunee-alloys zeWC-Co; okukhona iTiC ininzi, kokukhona ukumelana ne-oxidation kuqina.

Ubushushu be-oxidation yeTaC buphezulu kuneeWC, kwaye ii-alloys ezineTaC kunye neNbC ziphucule ukumelana ne-oxidation yobushushu obuphezulu. Nangona kunjalo, umxholo ophezulu we-cobalt wenza kube lula uku-oxidation.

Kutheni Ukhetha iChengduhuaxin Carbide?

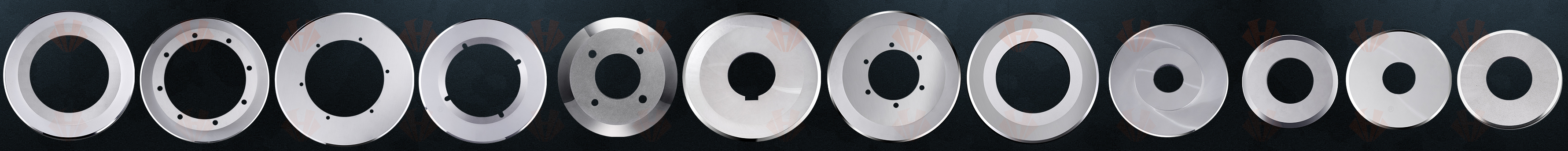

I-Chengduhuaxin Carbide ivelele kwimarike ngenxa yokuzinikela kwayo kumgangatho kunye nokuvelisa izinto ezintsha. Iiblade zabo zekhaphethi ze-tungsten carbide kunye neeblade ze-tungsten carbide ezifakwe kwi-slotted zenzelwe ukusebenza kakuhle, zibonelela abasebenzisi ngezixhobo ezibonelela ngokusika okucocekileyo nokuchanekileyo ngelixa bemelana nobunzima bokusetyenziswa kakhulu kwimizi-mveliso. Ngokugxila ekuqineni nasekusebenzeni kakuhle, iiblade ze-Chengduhuaxin Carbide ezifakwe kwi-slotted zibonelela ngesisombululo esifanelekileyo kumashishini afuna izixhobo zokusika ezinokuthenjwa.

I-CHENGDU HUAXIN CEMENTED CARBIDE CO., LTD ngumthengisi oqeqeshiweyo kunye nomvelisi weiimveliso ze-tungsten carbide,njengeemela zokufaka i-carbide zokusebenza ngomthi, i-carbideiimela ezijikelezayongenxaiintonga zokucoca icuba necuba, iimela ezijikelezileyo yokusika amakhadibhodi ane-corugat,iincakuba zereyiza ezinemingxuma emithathu/iincakuba ezinemingxuma yokupakisha, iteyiphu, ukusika ifilimu encinci, iiblade zokusika ifayibha kushishino lwelaphu njl.njl.

Ngophuhliso lweminyaka engaphezu kwama-25, iimveliso zethu zithunyelwe kwamanye amazwe e-US A, eRashiya, eMzantsi Melika, eIndiya, eTurkey, ePakistan, eOstreliya, eMzantsi-mpuma Asia njl. Ngomgangatho ogqwesileyo kunye namaxabiso akhuphisanayo, isimo sethu sengqondo sokusebenza nzima kunye nokuphendula kuyavunywa ngabathengi bethu. Kwaye singathanda ukuseka ubudlelwane obutsha beshishini nabathengi abatsha.

Qhagamshelana nathi namhlanje kwaye uya konwabela iingenelo zomgangatho olungileyo kunye neenkonzo ezivela kwiimveliso zethu!

Imibuzo eqhelekileyo yabathengi kunye neempendulo zeHuaxin

Oko kuxhomekeke kubungakanani, ngokubanzi iintsuku ezi-5-14. Njengomvelisi weeblade zoshishino, iHuaxin Cement Carbide iceba imveliso ngokwee-odolo kunye nezicelo zabathengi.

Ngokwesiqhelo iiveki ezi-3-6, ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Purchase & Delivery Conditions apha.

ukuba ucela iimela zoomatshini ezenzelwe wena okanye iiblade zemizi-mveliso ezingekhoyo ngexesha lokuthenga. Fumana iSollex Thenga kunye neMiqathango yokuHanjiswaApha.

Ngokwesiqhelo i-T/T, iWestern Union...idiphozithi kuqala, Zonke ii-odolo zokuqala ezivela kubathengi abatsha zihlawulelwa kwangaphambili. Ezinye ii-odolo zinokuhlawulwa nge-invoyisi...Qhagamshelana nathiukwazi okungakumbi

Ewe, nxibelelana nathi, iimela zemizi-mveliso ziyafumaneka ngeendlela ezahlukeneyo, kuquka iimela ezibekwe phezulu, iimela ezijikelezileyo ezantsi, iimela ezinamazinyo aqinileyo/amazinyo, iimela ezijikelezileyo ezigqobhozayo, iimela ezithe tye, iimela ze-guillotine, iimela ezitsolo, iimela ezibukhali, kunye neemela ze-trapezoidal.

Ukuze sikuncede ufumane eyona blade ilungileyo, iHuaxin Cement Carbide ingakunika iiblade ezininzi zesampulu oza kuzivavanya kwimveliso. Ukuze usike kwaye uguqule izinto eziguquguqukayo ezifana nefilimu yeplastiki, ifoyile, ivinyl, iphepha, nezinye, sinikezela ngeeblade zokuguqula kuquka iiblade zeslitter ezinezikhewu kunye neeblade zerazor ezinezikhewu ezintathu. Sithumelele umbuzo ukuba unomdla kwiiblade zomatshini, kwaye siya kukunika isaphulelo. Iisampulu zeemela ezenziwe ngokwezifiso azifumaneki kodwa wamkelekile ukuba u-odole ubungakanani obuncinci be-odolo.

Zininzi iindlela eziya kwandisa ixesha elide kunye nobomi beshelufu beemela zakho zoshishino kunye neeblayidi ezikhoyo. Qhagamshelana nathi ukuze wazi malunga nendlela efanelekileyo yokupakishwa kweemela zoomatshini, iimeko zokugcina, ukufuma kunye nobushushu bomoya, kunye neengubo ezongezelelweyo eziya kukhusela iimela zakho kwaye zigcine ukusebenza kwazo kokusika.

Ixesha leposi: Julayi-23-2025