Intshayelelo yezixhobo zemela zeCarbide!

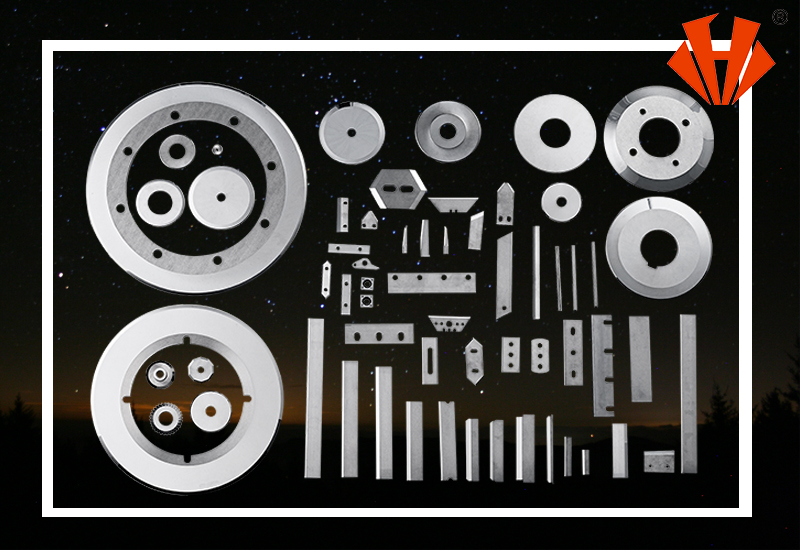

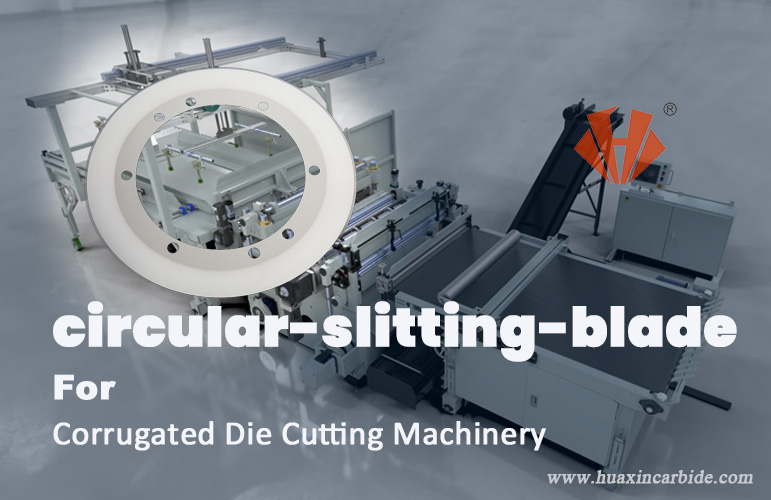

Izixhobo zemela yeCarbide

Izixhobo zeCarbide knife, ngakumbi izixhobo zeCarbide knife ezinokuboniswa, zezona mveliso ziphambili kwizixhobo zeCNC machining. Ukususela ngeminyaka yoo-1980, iintlobo ngeentlobo zezixhobo zeCarbide knife okanye i-inserts eziqinileyo nezinokubonwa ziye zanda zaya kwiindawo ezahlukeneyo zezixhobo zokusika. Izixhobo zeCarbide knife ezinokubonwa ziye zavela kwizixhobo ezilula zokujika kunye nezicucu zokusika ubuso ukuya kwizicelo ezahlukeneyo zezixhobo ezichanekileyo, ezinzima, nezokwakha.

A. Iintlobo zezixhobo zemela zeCarbide

Uhlulo ngokwendlela eMain Chemical Composition

Izixhobo zemela yeCarbide zinokwahlulwa zibe ziicarbides ezisekelwe kwi-tungsten carbide kunye neecarbides ezisekelwe kwi-titanium carbonitride (TiC(N)).

Iikhabhide ezisekelwe kwi-tungsten carbideziquka:

● YG (tungsten-cobalt): Ukuqina okuphezulu kodwa ubunzima obuphantsi.

● YT (tungsten-cobalt-titanium): Ubulukhuni obulinganiselayo kunye nokuqina.

● YW (eneekhabhayithi ezinqabileyo): Iimpawu eziphuculweyo ezinezongezo ezifana neTaC okanye iNbC.

Izinto eziphambili ziquka i-tungsten carbide (WC), i-titanium carbide (TiC), i-tantalum carbide (TaC), kunye ne-niobium carbide (NbC), kunye ne-cobalt (Co) njengesixhobo esiqhelekileyo sokubopha isinyithi.

Ii-carbides ezisekelwe kwi-titanium carbonitride zisebenzisa i-TiC njengeyona nto iphambili, zihlala zinezinye ii-carbides okanye ii-nitrides, kunye ne-Mo okanye i-Ni njengezihlanganisi.

Udidi lwe-ISO

I-International Organisation for Standardization (ISO) ihlela ukusika ii-carbides zibe ziindidi ezintathu:

● Udidi lwe-K (K10–K40): Ilingana ne-YG (WC-Co), kwisinyithi esityhidiweyo kunye neentsimbi ezingezizo iintsimbi.

● Udidi lwe-P (P01–P50): Ilingana ne-YT (WC-TiC-Co), yentsimbi.

● Udidi lwe-M (M10–M40): Ilingana ne-YW (WC-TiC-TaC(NbC)-Co), kwizicelo ezahlukeneyo.

Amanqaku abhalwe ukusuka ku-01 ukuya ku-50, nto leyo ebonisa ukuba aqala kubunzima obuphezulu ukuya kubunzima obuphezulu.

B. Iimpawu zokusebenza kwezixhobo zemela zeCarbide

● Ubunzima obuphezulu

Izixhobo zemela zeCarbide zenziwe nge-powder metallurgy ukusuka kwi-high-hardness, high-melting-point carbides (isigaba esiqinileyo) kunye ne-metal binders (isigaba sokubopha). Ubunzima bazo buqala kwi-89–93 HRA, buphezulu kakhulu kune-high-speed steel (HSS). Kwi-540°C, ubunzima buhlala kwi-82–87 HRA, xa kuthelekiswa ne-HSS kubushushu begumbi (83–86 HRA). Ubunzima buyahluka ngohlobo lwe-carbide, ubungakanani, ubungakanani bengqolowa, kunye nomxholo we-binder, ngokubanzi buyehla njengoko umxholo we-binder unyuka. Kumxholo ofanayo we-binder, ii-YT alloys zinzima kunee-YG alloys, kwaye ii-alloys ezine-TaC(NbC) zinobunzima obuphezulu bobushushu obuphezulu.

●Amandla okuGuquka kunye nokuqina

Amandla okugobeka kweekhabhide eziqhelekileyo aqala kwi-900–1500 MPa. Umthamo ophezulu we-binder wonyusa amandla okugobeka. Kumxholo ofanayo we-binder, ii-alloys ze-YG (WC-Co) zinamandla kunee-alloys ze-YT (WC-TiC-Co), amandla ancipha njengoko umxholo we-TiC usanda. Iikhabhide zibuthathaka, kwaye ubunzima bokuchaphazeleka kubushushu begumbi buyi-1/30 ukuya kwi-1/8 kuphela kune-HSS.

C. Ukusetyenziswa kwezixhobo zemela zeCarbide eziqhelekileyo

●IiCarbides zeKlasi yeYG

Ii-alloy ze-YG zisetyenziswa kakhulu ekubumbeni isinyithi esityhidiweyo, iintsimbi ezingezizo i-ferrous, kunye nezinto ezingezizo i-metallic. Ii-alloy ze-YG eziziingceba ezintle (umz., YG3X, YG6X) zinobunzima obuphezulu kunye nokumelana nokuguguleka kunee-alloy zengqolowa ephakathi ezinomxholo ofanayo we-cobalt, zifanelekile ekubumbeni isinyithi esiqinileyo esikhethekileyo, intsimbi engatyiwayo ye-austenitic, ii-alloy ezimelana nobushushu, ii-alloy ze-titanium, i-bronze eqinileyo, kunye nezinto zokugquma ezingagugiyo.

●IiCarbides zeKlasi yeYT

Ii-alloy ze-YT zinobunzima obuphezulu, zimelana kakuhle nobushushu, kwaye zinobunzima obuphezulu obuphezulu kunye namandla okucinezela kunee-alloy ze-YG, kwaye zimelana ne-oxidation ephezulu. Zilungele ukusetyenziswa kobushushu obuphezulu kunye nokumelana nokuguguleka kwaye zifanelekile ekutshixeni izixhobo zeplastiki ezifana nentsimbi kodwa kungekhona i-titanium okanye i-silicon-aluminium alloys. Amanqanaba aphezulu omxholo we-TiC akhethwa kakhulu kubushushu obuphezulu kunye nokumelana nokuguguleka.

● IiCarbides zeYW Class

Ii-alloy ze-YW zidibanisa iipropati zee-alloy ze-YG kunye ne-YT, zibonelela ngokusebenza okuhle ngokubanzi. Zifanelekile ekusetyenzweni kwentsimbi, isinyithi esityhidiweyo, kunye neentsimbi ezingezizo i-ferrous. Ngomxholo ophezulu we-cobalt, ii-alloy ze-YW zinamandla aphezulu, nto leyo ezenza zilungele ukwenziwa kwe-rough machining kunye nokusikwa okuphazamisekileyo kwezinto ezinzima ukwenziwa kumatshini.

Inkampani yeCarbide eCemented Chengdu Huaxin: Umvelisi oPhambili

Inkampani yeCarbide eCemented Chengdu Huaxinngomnye wabadlali abaphambili kushishino lwe-tungsten carbide blade eTshayina. Eyaziwa ngemigangatho yayo yokuvelisa ekumgangatho ophezulu kunye nokuzibophelela ekuveliseni izinto ezintsha zobuchwepheshe, iHuaxin izakhele igama elihle kwiimarike zasekhaya nezamazwe ngamazwe.

Kutheni Ukhetha iChengdu Huaxin Cemented Carbide?

- Imigangatho yoMgangatho:Iimveliso zikaHuaxin zilandela imigangatho engqongqo yomgangatho, ziqinisekisa ukuthembeka nokusebenza kakuhle.

- Izixhobo zoMveliso eziPhambili:Le nkampani isebenzisa izixhobo zokuvelisa kunye nobuchwepheshe obuphezulu ukuvelisa iiblayidi ezihlangabezana neemfuno ezichanekileyo.

- Uluhlu olubanzi lweeMveliso:IHuaxin inikezela ngeentlobo ezahlukeneyo zeeblade ze-tungsten carbide kumashishini ahlukeneyo, kuquka neendlela ezenziwe ngokwezifiso ezilungiselelwe iimfuno ezithile.

- Amaxabiso akhuphisanayo:Inkqubo enkulu yemveliso kunye neenkqubo ezisebenzayo zenkampani ziyenza ikwazi ukubonelela ngamaxabiso akhuphisanayo ngaphandle kokubeka emngciphekweni umgangatho.

- Inkonzo Yasemva Kokuthengisa:IHuaxin yaziwa ngenkonzo yayo egqwesileyo kubathengi, inika inkxaso yobugcisa kunye nesikhokelo ukuqinisekisa ukusebenza kakuhle kwemveliso.

Yazi ngakumbi malunga neHuaxin Cemented Carbide

Ukuze wazi ngakumbi ngamaxabiso kunye neenkonzo, nceda ucofe apha>>> Qhagamshelana nathi

---------

Ukuze wazi ngakumbi ngeNkampani yethu, nceda ucofe apha>>>Ngathi

---------

Ukuze wazi ngakumbi ngepotifoliyo yethu, nceda ucofe apha>>>Iimveliso Zethu

---------

Ukuze wazi ngakumbi nge-AfterSales yethu kunye nabanye abantu ababuza imibuzo, nceda ucofe apha >>> FAQ

Ixesha leposi: Juni-17-2025